From Gut-Feel to Gold Standard: Lion Paper’s Journey to Structured Quality Control

- Leo Xia

- Jul 28, 2025

- 5 min read

Quick Content Reach:

1. From Gut-Feel to Gold Standard: Lion Paper’s Journey to Structured Quality Control

“Quality is never an accident; it is always the result of intelligent effort.”

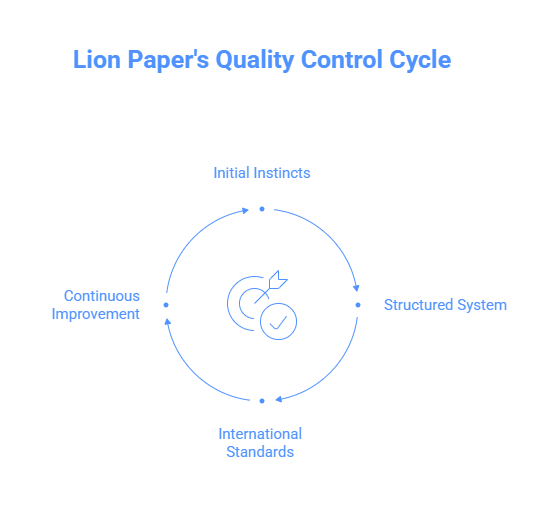

This quote resonates deeply with me. I’m Leo Xia, CEO of Lion Paper Products, and I’d like to share a journey that redefined how we guarantee excellence in every notebook, planner, journal, and calendar we produce. Our quality control process didn’t evolve overnight. It was a transformation, from gut-based instincts to a rigorously structured, system-driven operation grounded in international standards.

If you're sourcing writing paper products for retail or e-commerce, understanding our journey might help you find a more reliable, strategic supplier. And if anything here resonates with your needs, don’t hesitate to contact us or reach out.

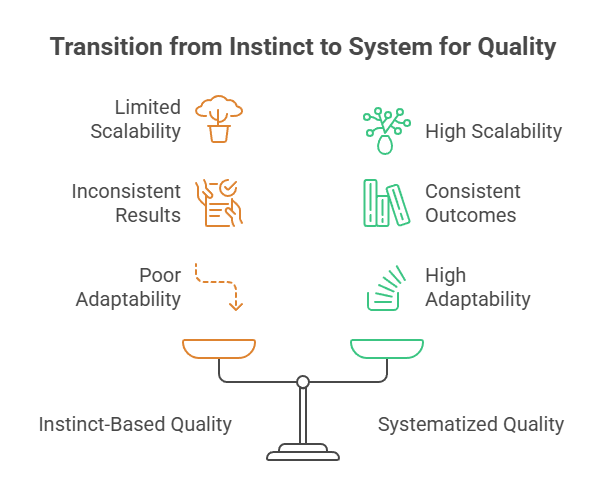

2. The Problem with Instinct-Based Quality Judgments

Before systematization, like many factories, we relied on experienced eyes and subjective checks. Our team had strong instincts, yes—but instincts are not scalable. When client requirements vary across the U.S., UK, Germany, or Australia, and you serve different sectors from boutique retailers to government procurement, "gut feel" doesn’t cut it.

We learned this the hard way. Missed defects, inconsistent reporting, and reactive problem solving jeopardized client trust. That’s when we decided: it was time to upgrade.

If your current supplier still operates this way, your brand might be at risk. Start the conversation with us today and see how our structured QC makes a difference.

3. Building Our Structured Quality Control (QC) Framework

Our journey began with one belief: quality must be designed, not inspected. That meant investing in:

ISO quality system certification

Certified quality testing regulations

20+ advanced machines, including Heidelberg Printing, Die-Cutting, Stamping Foil, and Visual Positioning Instruments for cover shell alignment

A team of 10+ full-time quality inspectors

Each inspector wears a video recorder, ensuring full transparency and traceability. Every inspection is documented, every issue traceable.

Benefit to you: Peace of mind knowing your orders meet high international benchmarks—from concept to carton. Let’s talk about your next project.

4. The Role of SOPs: From Chaos to Consistency

Creating SOPs (Standard Operating Procedures) was our next leap. Each step—from paper folding to spiral binding—is now:

Documented with detailed visual guides

Taught during worker training sessions

Embedded in our daily operations

No guesswork, no improvisation. For example, if you order a custom planner with gold stamping and rounded corners, every staff member follows the same exact process.

Your value: A consistently beautiful product, every time. Explore our custom notebook solutions and see how SOPs benefit your brand.

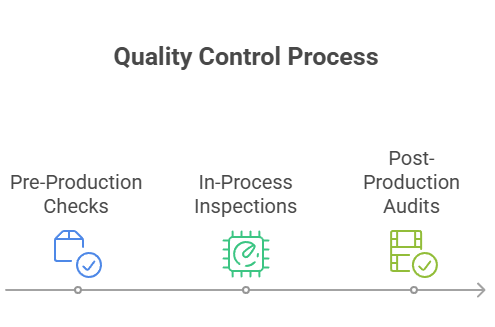

5. Quality Checks in Three Phases: Before, During, After Production

Our QC isn’t a one-time step. It’s a three-phase system:

1. Pre-Production Checks:

Cross-checking final samples against original specs

Verifying material quality (paper gsm, ink durability)

Reviewing packaging layout and shipping plans

2. In-Process Inspections:

Video and photo documentation at each stage

Real-time adjustments for detected anomalies

Tracking task completion rate vs production plan

3. Post-Production Audits:

80%+ of goods packed before final audit begins

Unified QC report with timestamped visuals

Immediate alerts to sales team for resolution

Why it matters to you: Whether you’re shipping to a U.S. bookstore chain or a Qatar distributor, consistency is critical. Contact us today to learn more about how we reduce error margins to <0.5%.

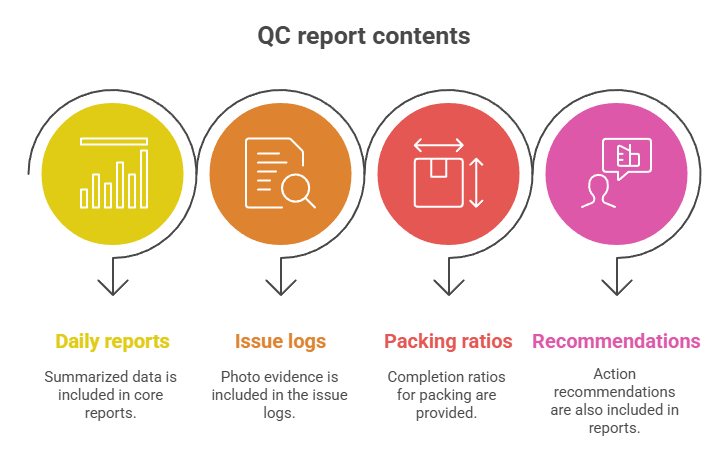

6. Data-Driven Reports: Less Subjectivity, More Clarity

No more vague terms like "mostly okay." Our QC reports include:

Core daily reports with summarized data

Issue logs with photo evidence

Packing completion ratios

Action recommendations

We simplified it with table-based visual reports and eliminated unnecessary repetition. Want a sample report to review? Email us.

7. Real-Time Communication & Transparent Feedback Loops

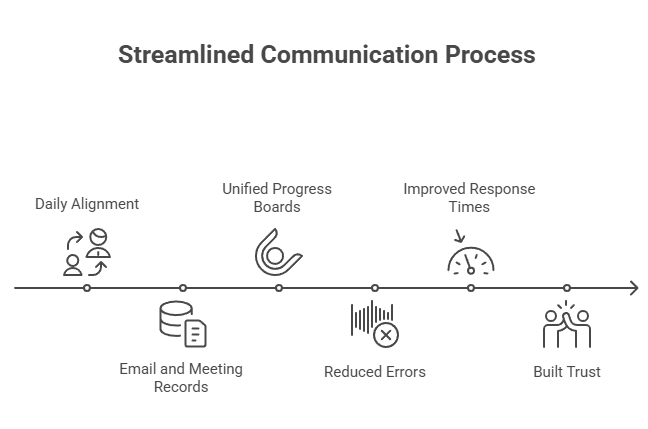

One of our breakthroughs? Streamlined cross-functional communication:

Daily alignment between factory, QC, and sales teams

Email and meeting records for traceability

Unified progress boards with task owners listed

It reduced errors, improved response times, and built real trust across stakeholders.

If you’re struggling with communication gaps from your current suppliers, we’re ready to show you a more transparent approach.

8. Emergency Response Protocols: Prepared, Not Panicked

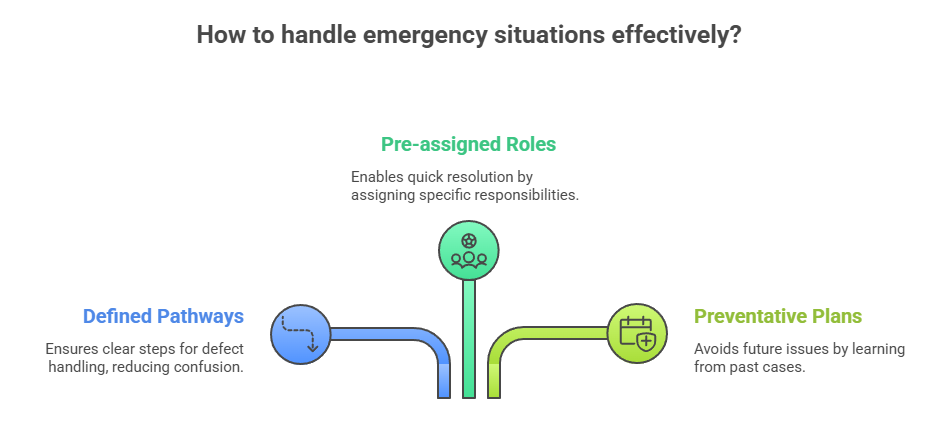

Sometimes, even top systems face hiccups. Our solution? Emergency SOPs.

Defined pathways for handling defects

Pre-assigned roles to QC and sales for fast resolution

Preventative intervention plans based on past cases

For example, if a planner's wire-O binding is off-center, we intervene during production—not after shipping.

Let’s discuss how our emergency readiness could save your next launch.

9. Worker Safety as Part of Quality Culture

Quality doesn’t stop with the product. It begins with people:

BSCI human rights certified

Workers equipped with cut-resistant gloves and protective overalls

Hands-on training for every piece of equipment

Healthy, skilled workers = fewer errors = better products.

Partner with a supplier who respects their team and delivers top results. Let’s connect.

10. International Certifications: Earning Trust, Not Just Orders

Your markets demand compliance. We’re ready:

ISO9001 (Quality management)

FAMA (Disney supplier compliance)

California Prop 65 (Toxin-free materials)

CPSIA (Child safety compliance)

GSV

One supplier, global compliance. Let’s build your brand together across borders.

11. A Culture of Continuous Improvement

Every 6 months, we conduct a QC review across 10 dimensions:

Task sheet management

Pre-production communication

On-site documentation

Report standardization

SOP building update

Emergency handling

Progress tracking

Cross-departmental collaboration

Data-backed evaluation

Optimizing quality responsiveness

It’s not just a report. It’s a mirror. And we use it to get better.

If you believe in continuous improvement like we do, we’re the partner you need. Reach out today.

Conclusion: Quality You Can Rely On

From instinct to system. From risk to repeatability. Our journey wasn’t easy—but it was worth it.

Because when your planners end up on a U.S. retailer's shelf or a German school desk, they should speak of reliability, elegance, and value. That’s the Lion Paper promise.

Let’s talk about your quality expectations. Contact me directly at Lily@lion-paper.com or on WhatsApp +86 137 5075 6354.

—Leo Xia, CEO, Lion Paper Products

You design, we deliver.

FAQs:

Q1: What certifications does Lion Paper have?

A: Lion Paper is ISO9001, FAMA, CPSIA, California Proposition 65, and GSV certified...

Q2: Do you offer emergency quality issue handling?

A: Yes. We have SOPs for emergency handling and defect control.

Q3: How do you ensure product consistency?

A: Through SOPs, training, real-time inspections, and transparent reporting.

Q4: Do you support eco-friendly options?

A: Yes. We support sustainable paper sourcing and toxin-free materials.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition!

Comments