A Simple Custom Guide to Square Notebooks

- Leo Xia

- Nov 3, 2025

- 14 min read

A square notebook offers a modern, balanced canvas. They come in sizes from pocket‑size to large and can be customized with lay‑flat binding, premium paper and finishes.

Quick Content Reach:

What Is a Square Notebook?

A square notebook is a journal or planner whose width and height are equal, producing a symmetrical page. While typical notebooks follow common rectangles like A5 or letter size, square notebooks create a balanced, contemporary look that appeals to designers, photographers and brands seeking a distinctive product. They offer a wider canvas for layouts, images and sketches and provide an eye‑catching alternative to the standard rectangle. The square format makes them popular in photo books, children’s titles, cookbooks and catalogs because pages can be divided evenly and arranged creatively.

Why Go Square?

Symmetry and visual appeal – Square pages offer a balanced, modern aesthetic. When paired with professional layouts, they create an elegant coffee‑table look and stand out on social media. For art and photography, the shape avoids wasted space and frames images naturally.

Versatility across genres – Square notebooks work for portfolios, planners, photo albums, cookbooks and design notebooks. Their layout suits both text and images and makes storyboards, diagrams and wireframes easier to organize.

Differentiation – In a market crowded with rectangular journals, a square notebook differentiates your brand. Unique shapes capture attention and encourage users to explore the product.

Shelf and storage friendly – Most square sizes are compact and easy to store. They stack neatly on shelves and in gift boxes without awkward overhangs.

Square vs. Rectangular

Format | Typical uses | Pros | Cons |

Square notebook | Art books, photo books, planners, catalogs | Modern, balanced aesthetic; ideal for images and grids; stands out on shelf | Unusual aspect ratio may require custom printing; may cost more than standard sizes |

Rectangular notebook | Everyday journals, lined paper pads, office supplies | Familiar size; fits standard filing and storage; cheaper to print | Less visually striking; landscape pages can make images feel constrained |

While rectangular notebooks remain practical for everyday note‑taking, square formats excel when design and presentation matter. Buyers who want to position products as premium or creative should explore custom square notebook options.

Have a square concept in mind? Email Leoxia@lion-paper.com or WhatsApp +86 137 5075 6354 for a fast feasibility check and free mockup advice.

Common Square Sizes & When to Use Them

Popular Sizes

Small (6 × 6 in or 150 × 150 mm) – Ideal for pocket planners, small sketchbooks, children’s board books and promotional giveaways. Small square notebooks are portable and affordable, making them great for events or bundled gifts.

Medium (8 × 8 in or 200 × 200 mm) – A versatile size suitable for journals, planners, photo albums and catalogues. It balances portability with a generous page area. Medium squares are a sweet spot for bullet journals and custom planners.

Large (10 × 10 in or 250 × 250 mm and above) – Used for premium coffee‑table books, portfolios, art collections and calendars. Large square notebooks provide expansive canvases for graphics, photography and marketing materials. Because larger sizes require more paper and sturdier binding, they are best for high‑value products.

Choosing the Right Size

Selecting the right size depends on function, budget and brand image:

Purpose – Planners and journals benefit from portable 6 × 6 in or 8 × 8 in formats. Art books and catalogs require larger sizes to display images without cropping.

Page count – Smaller square notebooks may need fewer pages to remain ergonomic. For lengthy manuals or catalogs, choose medium or large sizes with durable binding.

Cost considerations – Standard sizes are more economical because they minimize waste. Custom dimensions may increase cost. Align size with print signatures (multiples of 16 or 32 pages) to reduce excess sheets.

Branding and marketing – A dramatic 10 × 10 in book can become a conversation piece, while a pocket‑size square notebook can serve as a branded giveaway. Match the size to your target audience’s expectations.

Paper Choices—GSM, Finish & Anti‑Bleed

GSM Ranges

Paper weight (grams per square metre) affects how a square notebook feels and performs. Lighter paper is cost‑effective but may show through or bleed, while heavier stocks support ink and art.

< 80 GSM – Thin and lightweight; often used for low‑cost, mass‑produced notebooks. Thin paper can exhibit show‑through and bleed with fountain or gel pens.

80–100 GSM – Standard for everyday journals and planners; handles ballpoint pens but may still struggle with heavy inks.

100–120 GSM – Premium writing paper with minimal ghosting and bleed; ideal for custom square notebooks and bullet journals.

120 GSM and above – Heavyweight for artists and watercolour enthusiasts; supports markers, watercolours and calligraphy.

Surface & Standards

Paper texture influences writing feel and print quality:

Smooth (calendered) paper – Ideal for fine pens, crisp lines and digital printing. It resists feathering and provides professional clarity.

Textured (toothy) paper – Offers tactile appeal and works well with pencils and charcoal. Excessive roughness can cause pens to skip or snag.

Coated vs. uncoated – Coated stocks (gloss, matte or silk) provide a smooth surface for vivid colours and images, while uncoated papers have a natural feel and are easier to write on.

Choose acid‑free and archival papers to preserve artwork. Many clients look for FSC‑certified or recycled paper options (see sustainability section) to show environmental responsibility.

Reduce Ghosting/Bleed

Ghosting occurs when ink is visible on the reverse side; bleed happens when ink penetrates the paper. To minimize these issues:

Choose higher GSM – Papers above 100 GSM resist ghosting and bleed when used with gel or fountain pens.

Use fountain‑pen‑friendly finishes – Smooth or lightly coated papers prevent feathering and hold ink on the surface.

Test pens and markers – Provide test sheets or sample books for clients so they can evaluate performance.

Offer anti‑bleed options – Some manufacturers apply subtle coatings or create multi‑layer papers specifically designed to reduce bleed. Highlight these features when marketing your custom square notebook range.

Binding That Lays Flat

Binding influences durability, aesthetics and usability. A square notebook that opens flat enhances writing and sketching by eliminating page curvature.

Compare Options

Binding type | Page range | Lay‑flat ability | Durability | Typical use |

Saddle stitch | 8–64 pages | Opens mostly flat | Low | Short manuals, brochures |

Perfect binding (glue) | 32–300 pages | Does not lay flat | Medium | Novels, catalogs |

Sewn perfect binding | 32–300 pages | Better lay‑flat than glued perfect | High | Premium journals |

Hardcover (case) | 40–500 pages | Moderate lay‑flat if sewn | Very high | Coffee‑table books |

Spiral/Wire‑O | 16–200 pages | Lays completely flat & rotates 360° | Medium | Planners, sketchbooks |

Thread‑bound (sewn signatures) | 80–300 pages | Lays flat | High | Premium notebooks |

Loose‑leaf/ring binder | Variable | Lays flat; pages removable | High | Binders for notes |

Thermal binding | 30–200 pages | Minimal lay‑flat | Medium | Reports; professional documents |

Score Each Method

Saddle stitch – Affordable and perfect for short square notebooks (max ~64 pages). It lays relatively flat but cannot handle thick books and is less durable. Use it for event programs, lookbooks or promotional brochures.

Perfect binding – Glued spines create a clean, professional edge. Suitable for 32–300 pages but does not lay fully flat, making note‑taking more challenging.

Sewn perfect binding – Combines glued and sewn signatures; increases durability and allows pages to open closer to flat.

Hardcover/case binding – Adds weight and durability. When signatures are sewn, hardcover books open relatively flat; ideal for high‑end presentation.

Spiral and Wire‑O – Offer the best lay‑flat performance because the coil allows each page to rotate 360°. Perfect for planners and sketchbooks but coils may catch on items.

Thread‑bound – Sewn sections create a premium feel; the book opens flat and pages stay secure.

Loose‑leaf/ring – Provides flexibility for adding/removing pages; heavy and bulky.

Thermal binding – Gives a polished look but pages cannot be removed; not ideal when full lay‑flat writing is needed.

When designing a custom square notebook, match binding to page count and end use. For professional planners, spiral or thread‑bound options are often preferred because they lay flat and allow users to write comfortably.

Inside Pages—Lined, Dot Grid, Blank, Square Grid

Pick by Use

Different ruling styles change how a square notebook can be used:

Dot grid – Dotted pages offer the flexibility of blank paper with subtle guides. Dots provide structure without dominating the design, making them ideal for bullet journaling, hybrid note‑taking and sketching. Users can create charts, calendars or habit trackers easily.

Square (grid) – Printed square grids divide the page into small squares. This ruling supports planning, engineering sketches, diagrams and architectural designs. Grid pages are excellent for custom planners, logbooks and game design. A grid square notebook can be used as a daily planner when lines alone are insufficient.

Blank – Unruled pages encourage creativity and freeform drawing. Artists, designers and children benefit from blank pages, although they can lead to crooked writing and irregular spacing.

Ruled – Lined pages are the traditional choice for note‑taking and journaling. They provide clear guidance for writing but limit drawing and may interrupt visual layouts.

Useful Add‑ons

Enhance the user experience with thoughtful additions:

Page numbers & index pages – Aid organization and cross‑referencing.

Ribbon bookmark – Keeps your place; optional multiple ribbons for planners.

Pocket at back – Holds receipts, business cards or ephemera.

Elastic closure – Protects pages and keeps the notebook closed during transport.

Custom endpapers – Print brand patterns or inspirational quotes inside the covers.

Perforated pages – Allow users to tear out notes cleanly.

Table of contents or key – Particularly useful for bullet journals.

Combining these features with the correct ruling style results in a functional and appealing square notebook.

Covers & Finishes

Materials

Choosing the right cover material elevates your square notebook and reflects brand values:

Cloth – Linen or cotton covers feel upscale and can be foil‑stamped or debossed. They pair well with sewn bindings and hardcover formats.

Leather or faux leather – Offers a luxurious look and durability; suitable for executive journals.

Paper or board – Allows full‑color printing and laminations; an economical choice for softcover planners.

PU/Synthetic – Provides a leather‑like appearance at lower cost; available in many textures and colours.

Lamination – Gloss, matte or silk lamination adds a protective layer and enhances durability.

Varnish – Liquid coating that can be gloss, matte or satin; applied overall or only in select areas (spot varnish) to add subtle sheen.

Spot UV – Uses UV‑cured varnish on specific design elements, creating high‑contrast shine on logos or text.

Foil stamping – Adds metallic or coloured foil to logos or titles, giving a premium appearance.

Embossing & debossing – Embossing raises images or text, adding tactile depth; debossing pushes them down. These techniques can be combined with foil stamping for dramatic effects.

Brand‑Safe Layout

Maintaining consistent margins and safe zones ensures a professional result:

Bleed and safety – Extend backgrounds and images beyond the trim size by at least 3 mm (0.125 in) to avoid white edges during cutting. Keep logos and text within safe margins so they aren’t trimmed off.

Spine width – Calculate spine width based on page count and paper thickness. Always allocate a no‑print area to prevent cracking.

Logo placement – Place logos in the upper or lower third of the cover to maximize visibility. Avoid placing critical elements near edges where they could be trimmed.

Design & File Specs

Color Modes

CMYK – Print files should be prepared in CMYK (cyan, magenta, yellow and black) because printers use this subtractive colour model. Converting from RGB to CMYK can dull colours; working natively in CMYK avoids unexpected shifts.

Pantone (spot) colours – For corporate branding, specify Pantone spot colours alongside CMYK to achieve precise brand hues. Spot colours are printed separately and incur additional cost but ensure accuracy.

Bleed & Minimums

Bleed – Extend artwork 3 mm beyond final trim size to prevent white edges. Use print‑ready templates with built‑in bleed guides.

Safe zone – Keep all text and important elements at least 3 mm inside the final trim size to avoid trimming.

Line thickness & font size – For offset printing, maintain minimum stroke thickness of 0.25 pt; digital printing requires at least 0.5 pt to ensure clarity. Text smaller than 6 pt can become illegible; 8–10 pt is recommended for body copy.

Resolution – Use 300 DPI images for crisp output. Avoid enlarging low‑resolution images, as pixelation will be obvious on the printed page.

Templates

Provide clients with pre‑scaled templates to simplify design. Common sizes include 6 × 6 in, 8 × 8 in, 10 × 10 in and 12 × 12 in pages. Templates should include bleed and safety guides, spine area and note recommended font sizes and line weights. Export final artwork as high‑resolution PDF/X files for reliable prepress handling.

MOQ, Lead Time & Cost Factors

What Drives Cost

Several variables determine the price of a square notebook:

Quantity – Larger print runs reduce per‑unit cost due to economies of scale. Many suppliers offer significant discounts at 500, 1 000 or 5 000 units.

Size and page count – Bigger formats use more paper and heavier binding; thick books require stronger covers and adhesives. Align page count with printer signatures (multiples of 16 or 32) to avoid paying for blank sheets.

Paper type – Premium, recycled or specialty papers cost more. Opting for standard weights and finishes keeps budgets under control.

Binding – Saddle stitch is the least expensive; hardcover and sewn bindings increase cost due to materials and labor.

Colour vs. black & white – Full‑colour printing increases ink and prepress costs. Using spot colours wisely can balance aesthetics and budget.

Finishes & extras – Foil, embossing, die‑cut windows or inserted pockets add to the unit price.

Location & shipping – Printing locally may be more expensive but reduces freight costs. Overseas production can be cheaper but requires longer lead times. Budget for import duties and customs.

Proofing Strategy

To avoid costly mistakes:

Digital proof – Receive a PDF proof to check layout, colours and pagination before printing.

Bound dummy – For large orders, request a physical dummy to confirm paper feel, binding and spine width.

Colour checks – If colour accuracy is critical, ask for a printed proof on your chosen paper to ensure brand colours match expectations.

Timeline

A typical production workflow for custom square notebooks is:

Quote & consultation – Discuss size, materials, quantity and budget. Suppliers may provide price tiers based on order volume.

File check – Submit design files; prepress technicians verify bleed, resolution and colour modes.

Proof approval – Review digital or physical proofs and confirm corrections.

Production – Printing, binding and finishing; time varies by quantity and complexity.

Quality control – Inspect final products; adjust if necessary.

Shipping – Choose standard (10–25 days estimated) or express (5–10 days estimated) shipping. For large orders, palletized freight is more cost‑effective.

MOQs & Lead Time

Most printers set a minimum order quantity (MOQ) because set‑up costs are high. Typical MOQs range from 500 to 1,000 units for custom square notebooks. Production usually takes 15-20 days depending on customization level, with shipping adding another 10–25 days based on destination and method. When negotiating, ask whether the supplier can accommodate smaller trial orders and how scaling up affects per‑unit pricing.

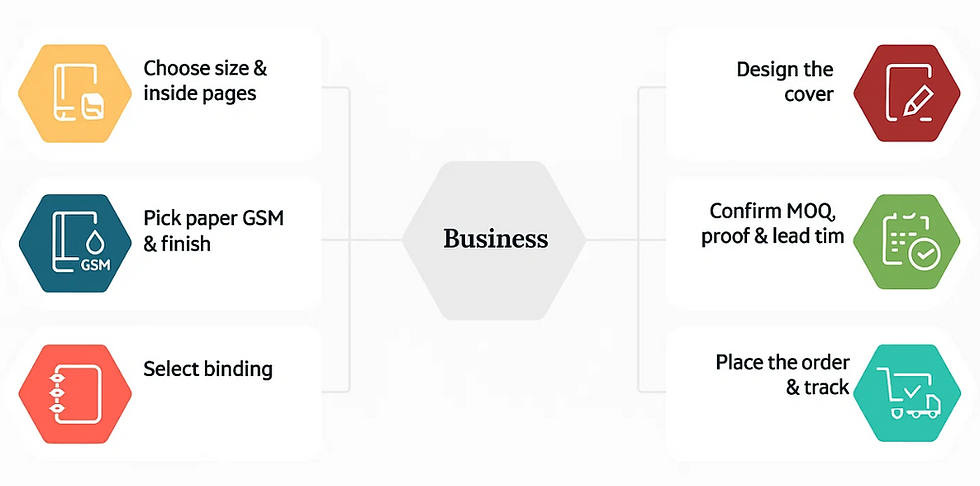

Step‑by‑Step—Customize Your Square Notebook

Choose size & inside pages – Decide between standard sizes like 6 × 6 in, 8 × 8 in or custom dimensions. Select ruling style (dot grid, square grid, lined or blank) based on usage and add‑ons like page numbers or pockets.

Pick paper GSM & finish – Match paper weight to your pens and budget. Standard 100–120 GSM works for most writing; upgrade to 120+ GSM for watercolours. Choose smooth or textured surfaces.

Select binding – For lay‑flat usability, opt for spiral/Wire‑O or thread‑bound; choose perfect binding for catalogs or marketing brochures. Hardcovers suit premium gifts.

Design the cover – Create a striking cover using your brand colours. Prepare artwork in CMYK, include a 3 mm bleed and keep critical elements within safe margins.

Confirm MOQ, proof & lead time – Request quotes and proofs. Approve digital or physical proofs before printing. Ensure the timeline matches your launch or campaign date.

Place the order & track – Finalize the order, complete payment and track production. Communicate with the manufacturer to monitor milestones and ensure delivery.

Care, Packaging & Sustainability

Eco Options

Sustainability is a selling point for today’s buyers. Choosing eco‑friendly materials reduces environmental impact and enhances brand reputation.

FSC‑certified paper – The Forest Stewardship Council certifies paper sourced from responsibly managed forests. Using FSC‑certified paper ensures materials come from sources that protect the environment, respect social rights and support economic viability.

Recycled paper – Made from post‑consumer waste; benefits include forest preservation and a reduced carbon footprint.

Soy‑based inks – Vegetable‑based inks such as soy produce fewer volatile organic compounds (VOCs) and provide vibrant colours, making them more sustainable than petroleum‑based inks.

Energy‑efficient printing – LED UV and digital printing consume less energy and minimize waste, contributing to a lower carbon footprint.

Packaging

Proper packaging protects the square notebook during transit and enhances presentation:

Individual wrapping – Each notebook can be shrink‑wrapped or placed in a protective sleeve to shield it from dust, moisture and scratches.

Bulk packaging – Stack notebooks in reinforced corrugated boxes with cushioning materials to prevent bending or impact damage.

Custom packaging – Premium orders can include branded gift boxes or protective cases. Luxury options may feature tissue paper, ribbon or kraft paper for an eco‑friendly touch.

Labeling & documentation – Ensure packages are clearly labelled with order details and customs declarations.

Transit Protection

Shipping methods vary by budget and urgency:

Standard shipping (10–25 days) – Budget‑friendly for bulk orders.

Express shipping (5–10 days) – Ideal for urgent orders.

Freight & bulk cargo – For large orders, palletized shipping via air or sea reduces per‑unit cost.

Tracking & insurance – Choose carriers that offer real‑time tracking and insurance against loss or damage.

Sustainability also applies to packaging choices. Use recyclable or biodegradable packing materials and minimize plastic. Communicate your eco commitments by adding an FSC or recycling logo on packaging.

Final Words

A square notebook can transform an ordinary journal into a signature piece that expresses your brand’s creativity and quality. By understanding size options, paper weights, binding methods, page rulings and finishes, you can design a notebook that meets functional needs and delights users. Follow technical specs—3 mm bleed, CMYK colour, adequate line weights—and invest in eco‑friendly materials like FSC‑certified paper, recycled stocks and soy inks to align your product with sustainable values. With careful planning, proofing and packaging, your custom square notebook will stand out in the marketplace and showcase the professionalism of your brand.

If you’re ready to start designing your own square notebook, my team at Lion Paper Products can guide you through every step—from concept and prototypes to final production. Contact us at Lion Paper Products for personalized advice.

Whether you need a pocket‑size notebook for events or a luxury coffee‑table book, we offer end‑to‑end solutions, eco‑friendly options and a proven supply chain that meets international standards. Let’s bring your vision to life—leave your requirements today!

—Leo Xia, CEO, Lion Paper Products

You design, we deliver.

FAQs:

Q1: What is a square notebook and how is it different from a regular notebook?

A: A square notebook has equal width and height, offering a balanced, modern layout. Compared with rectangular notebooks, square formats provide a unique canvas for photos, drawings and grids, making them ideal for creative projects.

Q2: What paper weight (GSM) is best for square notebooks?

A: For everyday writing, 80–100 GSM works well, while premium notebooks often use 100–120 GSM or more to reduce ghosting and bleed.

Q3: What finishes can I add to my square notebook cover?

A: Popular finishes include gloss, matte or silk lamination, spot UV, foil stamping, embossing and debossing. Each adds texture and visual interest.

Q4: Is eco‑friendly printing available?

A: Yes. You can choose FSC‑certified or recycled paper, soy‑based inks and energy‑efficient printing processes to reduce environmental impact.

Q5: How should square notebooks be packaged for shipping?

A: Individual notebooks can be shrink‑wrapped or placed in sleeves; bulk orders should be stacked in reinforced boxes with cushioning materials. Premium orders may use branded gift boxes or eco‑friendly kraft packaging.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition!

About Lion Paper

Company Name: Lion Paper Products

Office Address: 20th floor, Chuangyedasha Building, No. 135, Jinsui Road, Jiaxing City, Zhejiang Province, China

Factory Address: No.135, Xuri Road, Jiaxing City, Zhejiang, China

Email: Leoxia@lion-paper.com

Comments