Choosing Notebook Cover Finishes: A Quick Guide

- Lion Paper Team

- Jun 17, 2025

- 4 min read

Quick Content Reach:

How to Choose Notebook Cover Finishes for your Brand?

Struggling to make your notebooks stand out on the shelf—or survive the shipping journey intact?

Your cover finish could be the problem. A poorly chosen finish doesn’t just dull your design—it can lead to scratches, warped covers, or a product that feels cheap in the hand.

Choosing the right notebook cover finish is more than a visual decision—it's a strategic move. Whether you're sourcing for a school program, corporate client, or retail launch, your choice of lamination, varnish, or stamping can directly impact brand perception, shelf appeal, and even durability during shipping.

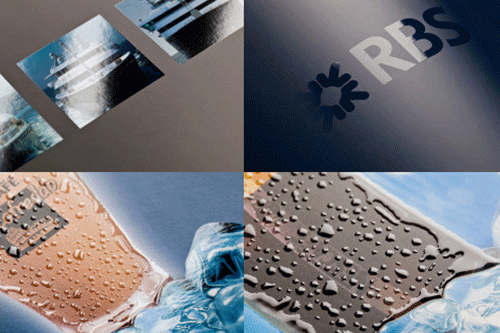

1. Lamination

What is Lamination?

Lamination involves applying a thin plastic film (usually BOPP or PET) over the cover to protect and enhance print quality.

Two Main Types

Gloss Lamination: Enhances colors, adds vibrancy and shine. Ideal for children’s notebooks or cosmetics brands.

Matte Lamination: Offers a premium, velvet-like feel. Popular in luxury gifting or executive planners.

When to Choose Lamination?

Products displayed in high-traffic retail stores

Full-bleed artwork or photo-heavy covers

Need protection against scratches and moisture

2. Varnishing

What is Varnishing?

A clear liquid coating applied directly to the printed sheet to add gloss, protection, or texture. Varnish can be aqueous (water-based), UV-cured, or oil-based.

Types of Varnishes:

Gloss

Matte

Satin

Why It Works:

Budget-friendly

Fast-drying (especially UV)

Eco-friendly (water-based = VOC-free)

What is Foil Stamping?

It uses heat and pressure to transfer metallic foil onto the surface—ideal for logos, accents, or luxury positioning.

Common Foil Types:

Gold

Silver

Holographic

Custom Colors

Best For:

Brand-name notebooks or premium planners

Corporate gifts with strong brand identity

Wedding, anniversary, or commemorative editions

4. Embossing & Debossing

What’s the Difference?

Embossing: The design is raised from the surface.

Debossing: The design is pressed into the material.

Why Use It?

Adds tactile value and luxury feel

Pairs well with foil stamping

No need for ink or color

5. Spot UV

What is Spot UV?

A UV-cured coating applied only to specific areas of a cover—like logos, titles, or graphics—to create contrast with the rest of the matte background.

Why Spot UV Stands Out:

Excellent for minimalistic branding

Adds subtle shine without being overwhelming

Creates focal points without using additional colors

Which Finish Should You Choose?

Finish | Best For | Pros | Considerations |

Lamination | Retail, humid areas, luxury gifts | Scratch resistance, vibrant print, waterproof | Higher cost, not biodegradable |

Varnish | Budget projects, eco-packaging | Fast, cheap, recyclable | Less durable than film lamination |

Foil Stamping | Luxury branding, gifts, logo design | Elegant, eye-catching, premium image | Adds cost, needs precision alignment |

Emboss/Deboss | Tactile luxury, artistic covers | Adds texture, no ink needed | Best paired with other finishes |

Spot UV | Modern brands, subtle highlights | Stylish, subtle, emphasizes design elements | Works best on matte background |

Conclusion

Choosing the right notebook cover finish isn’t about trends—it’s about making the right impression, matching your product’s purpose, and optimizing your unit cost. Whether you're sourcing for a retail launch or designing a luxury corporate gift, the finish you select can elevate your brand.

FAQs:

Q1: What is the most durable notebook cover finish?

A: The most durable finish is lamination, especially PET gloss lamination, which provides excellent scratch resistance, water resistance, and tear protection—ideal for notebooks used in high-touch environments like schools or retail stores. It's also less prone to discoloration during sea freight.

Q2: Is lamination environmentally friendly?

A: Standard lamination uses plastic film, which is not biodegradable. However, eco-laminates (e.g., biodegradable PLA films or water-based coatings) are available and increasingly popular among sustainability-driven brands. You can also choose varnish as an alternative for curbside recyclability.

Q3: What’s the difference between gloss and matte?

A: Gloss finishes create a shiny, reflective surface that enhances color vibrancy—ideal for visual appeal in retail. Matte finishes, on the other hand, offer a smooth, soft-touch look and reduce glare—better for luxury and minimalist brands.

Q4: Can I combine foil stamping with embossing?

A: Yes. Foil + embossing is a classic premium combination. It enhances tactile feel and gives your logo or graphics a 3D, shimmering effect. This combo is frequently used in high-end journals, luxury packaging, and corporate gift editions.

Q5: Which finish is best for luxury gifting?

A: We recommend soft-touch matte lamination combined with gold foil stamping or embossing. This creates a premium, tactile, and elegant presentation that aligns with upscale gifting aesthetics.

Q6: How long does Spot UV take to dry?

A: Spot UV is UV-cured, meaning it dries instantly under UV light. This fast curing makes it ideal for projects with tight timelines while still delivering sharp, high-contrast finishes.

Q7: Can I print on embossed areas?

A: Technically yes, but it’s not recommended. Ink may not apply evenly on raised surfaces, resulting in print distortion. It’s best to print first and then emboss for clean alignment and visual clarity.

Q8: Which finish is best for minimal branding?

A: Matte lamination with Spot UV is the top choice. The contrast between matte texture and glossy accents adds subtle elegance—perfect for minimal, modern notebook designs.

Q9: Do you offer finish sampling?

A: Yes, we offer sample customization for most cover finishes. Our R&D team can prepare mockups within 5–7 working days, with fast global shipping options for review and approval.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition.

Comments