What is the difference between lay flat binding and perfect binding?

- Leo Xia

- Aug 20, 2025

- 12 min read

Quick Content Reach:

Introduction: why binding choice matters

As the CEO of Lion Paper Products, I have spent two decades working and helping stationery buyers choose the right notebook for their brands. One of the most frequent questions I hear is “what is the difference between lay‑flat binding and perfect binding?” Both binding methods are popular for custom paper notebooks, planners and journals, yet they serve very different purposes. Lay‑flat binding uses a free‑floating spine and durable polyurethane (PUR) adhesive so that pages lie completely flat; perfect binding glues the pages and cover together for a sleek, square spine but does not open all the way.

In this article I will share data‑driven insights on durability, cost, design flexibility, printing quality and production time, with the goal of helping you choose the right binding for your next project.

As you read, feel free to contact me through Lion Paper Products or send an email to Lily@lion-paper.com if any part of the article sparks questions – your inquiry will help us tailor a perfect solution for your brand.

What is lay‑flat binding?

Lay‑flat binding, sometimes called Otabind or flexbind, is designed so that a book opens 180 degrees and the pages lay completely flat on a table. Technically, the pages are printed in signatures (groups of pages), then sewn or glued together with a flexible PUR adhesive and attached to a free‑floating spine. Unlike perfect‑bound books where the cover wraps tightly around the glued pages, lay‑flat books have a flexible hinge that separates the cover from the text block. This construction prevents pages from warping or curling; according to Graphic Finishing Services, lay‑flat binding “allows pages to lay completely flat when opened and prevents them from warping over time”gfsmn.com. PhotoBook Press echoes this advantage by stating that lay‑flat books prevent edges from curling because the spine is not stressed photobookpress.com. The strong PUR adhesive draws moisture from the air during curing, forming a bond up to 50 % stronger than conventional EVA glue used in standard perfect binding printivity.com.

From an aesthetic perspective, lay‑flat books are ideal for panoramic images and seamless spreads. Because the pages are joined in the middle without a tight crease, images printed across two pages remain uninterrupted. The GFS comparison notes that lay‑flat photobooks offer seamless spreads with no gutter loss across double‑page spreads and can accommodate up to 200 pages gfsmn.com. This makes lay‑flat binding popular for premium photo books, design portfolios, art catalogues and high‑end notebooks where image quality and user experience are paramount. The robust construction also appeals to business buyers who want their notebooks to withstand frequent opening and closing.

What is perfect binding?

Perfect binding is the workhorse of the soft‑cover book world. In this method, the printed pages are collated, their spines are roughened to improve adhesion, and then they’re glued together along the spine with either EVA (ethylene‑vinyl acetate) or PUR (polyurethane reactive) adhesive. A cardstock cover wraps around the glued pages and is trimmed flush, creating a clean, square spine. Perfect binding is widely used for paperback books, magazines, catalogues, training manuals and marketing materials because it offers a polished appearance at a cost‑effective price. The PhotoBook Press article notes that perfect binding is more affordable because of its simple construction process photobookpress.com. While PUR adhesives can also be used in perfect binding, many printers still use EVA glue because it sets quickly and is inexpensive printivity.com.

However, perfect binding comes with trade‑offs. The pages are fixed directly to the spine, so the book does not open fully; readers often need to hold the pages down, and the spine may show creasing. The GFS comparison explains that perfect bound books may have visible spine creasing, and images can become distorted if the binding is not done correctly gfsmn.com. In addition, the adhesive bond can weaken if the book is exposed to moisture or extreme temperatures; PhotoBook Press cautions that adhesive glue can cause pages to come apart over time if exposed to moisture photobookpress.com. Perfect binding is best for longer runs of novels, corporate reports and manuals where cost and professional appearance matter more than 180‑degree opening.

Durability: how do lay‑flat and perfect binding hold up?

Durability is often the first consideration for B2B stationery buyers. Lay‑flat binding is engineered for longevity: the flexible hinge and superior PUR adhesive create a spine that resists cracking and allows the book to lie flat without stressing the paper. Graphic Finishing Services notes that lay‑flat binding allows pages to stay together over time and use gfsmn.com. PUR adhesive bonds paper fibres at a molecular level; Printivity explains that PUR bond strength can be 50 % greater than EVA once the adhesive has fully set printivity.com. Because PUR adhesives cure by absorbing moisture, they are resistant to heat, cold and ink migration – they won’t re‑melt under high temperatures or crack in extreme cold printivity.com. These properties give lay‑flat books exceptional durability, making them suitable for corporate presentations, architectural portfolios and premium journals that need to last for years.

Perfect binding can also be durable when high‑quality PUR glue is used; however, many commercial printers use EVA adhesives because they cure quickly and cost less. EVA glue forms a strong bond for general use, but it is less flexible and can become brittle or crack with repeated opening. Printivity notes that EVA adhesives have lower cost and ease of operation but are susceptible to reactivation by heat and can crack in cold temperatures printivity.com. For paperback novels and magazines intended for casual reading, EVA perfect binding is adequate. For notebooks expected to endure daily use, we recommend specifying PUR adhesive or choosing lay‑flat binding.

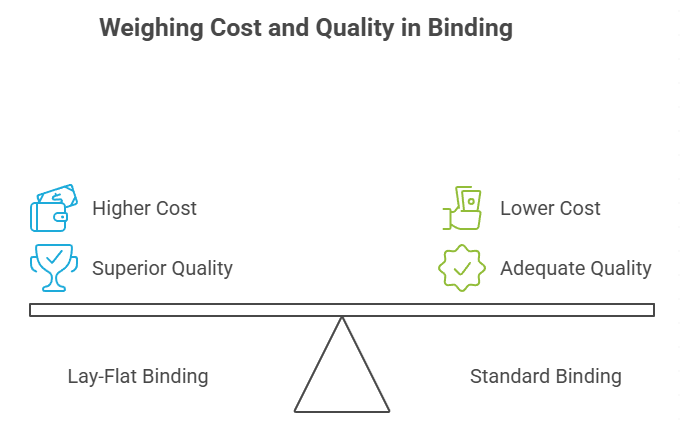

Cost considerations

Cost is a critical factor for procurement teams balancing budgets and quality. Lay‑flat binding delivers premium functionality but at a higher cost due to its complex assembly. Each signature must be carefully aligned, glued with PUR adhesive and attached to a free‑floating spine. Both GFS and PhotoBook Press stress that lay‑flat binding provides superior quality but comes at a higher cost because of the extra work involved gfsmn.comphotobookpress.com. The additional steps require skilled labour and often slower production speeds, which increase unit costs. If your project demands top‑tier presentation – such as a high‑end journal or promotional photobook – the investment may be justified.

Perfect binding, by contrast, is more economical. It involves a single step of gluing the pages together and wrapping the cover, resulting in lower labour time and less expensive materials. Both sources agree that perfect binding is more affordable photobookpress.com, making it ideal for large‑quantity orders like catalogues, product manuals and training guides.

If your priorities include budget efficiency and professional appearance, perfect binding may be your best choice. To make sure you get a precise estimate, contact our sales consultants; we can provide tiered pricing for both lay‑flat and perfect binding so you can compare them side by side.

Comparing cost factors (summary)

Factor | Lay‑flat binding | Perfect binding |

Labour | Requires precise alignment of signatures, application of PUR glue, free‑floating hinge – higher labour cost | Simple glue application and trimming – lower labour cost |

Materials | Uses PUR adhesive (more expensive), thicker cover stock; often includes reinforced hinges | Uses EVA or PUR adhesive (lower cost), standard cover stock |

Production speed | Slower due to curing and manual binding | Faster due to automated processes |

Unit cost | Higher, especially for small runs | Lower, economical for large runs |

Design flexibility and layout possibilities

Another key difference between lay‑flat and perfect binding is design flexibility. Lay‑flat books allow designers to spread content seamlessly across the gutter (the space between two facing pages). The unique binding mechanism ensures there is no gutter loss across double‑page spreads gfsmn.com. That means photos, charts, infographics and branding elements can flow uninterrupted from left to right, creating stunning panoramic presentations. For example, photographers love lay‑flat photobooks because panoramic images can spread over two pages without distortion, as emphasised by both GFS and PhotoBook Press gfsmn.comphotobookpress.com. In addition, lay‑flat binding supports more page count options (up to around 200 pages) gfsmn.com, providing greater flexibility for thick notebooks or catalogues.

Perfect binding, by contrast, has limitations in layout flexibility. The spine crease can cause images or lines of text to disappear near the gutter, and designers must account for “creep” (the slight shifting of page margins when a book is trimmed). Double‑page spreads can be used, but there is always a small gap in the middle where the pages meet. For notebooks with heavy text or separate sections, these limitations may be less important.

Layout planning tips

Full‑bleed images: Use lay‑flat binding for photographic spreads or infographics that span two pages. Perfect binding requires additional gutter margins to avoid losing content.

Page count: Consider lay‑flat binding for books up to 200 pages; perfect binding is more efficient for longer books or large print runs.

Brand storytelling: Use lay‑flat spreads for storytelling or product showcases; the uninterrupted canvas delivers high emotional impact. For technical manuals, perfect binding offers cost efficiency.

If you’d like assistance in planning your notebook layout, our experienced designers are available to review your project and suggest the best binding method. Feel free to email or WhatsApp us to schedule a consultation.

Printing quality and image reproduction

When evaluating binding options, image reproduction and print quality are essential. Lay‑flat books excel in this area. Both GFS and PhotoBook Press highlight that lay‑flat binding ensures photos and images are printed on both sides of each page and that the binding helps maintain sharpness and colour accuracy gfsmn.comphotobookpress.com. Because the book lies flat, there is no curvature to distort the image, making it ideal for high‑resolution artwork, architectural drawings or technical illustrations. Printivity notes that PUR adhesive applies a thinner coating than EVA and offers superior flexibility, reducing spine distortion and creating a cleaner appearance printivity.com. This combination of strong, flexible adhesive and flat opening preserves the integrity of images and text.

Perfect binding can deliver good print quality for text‑heavy documents, magazines and novels. However, because the pages do not lay flat, images printed near the gutter may appear slightly warped. PhotoBook Press mentions that the thickness of the glue in perfect binding can reduce image quality, making it better suited for books with text rather than photo‑heavy content photobookpress.com. Additionally, visible spine creasing in perfect‑bound books can distort images if not trimmed properly gfsmn.com. For product catalogues or visual presentations, lay‑flat binding will deliver more polished results. If your publication is primarily text (e.g., a training manual or novel), perfect binding remains a cost‑effective and professional option.

Production time and efficiency

Production time directly affects your project’s schedule and inventory planning. Lay‑flat binding generally requires more steps and longer curing times than perfect binding. PhotoBook Press explains that lay‑flat books need special paper that can bend easily, must be cut with a knife and aligned precisely, then glued together and bound by hand photobookpress.com. GFS emphasises that lay‑flat books take longer to produce because multiple steps are involved gfsmn.com. The curing of PUR adhesive can take 24 hours or more, which extends the timeline for final delivery.

Perfect binding is much faster. The pages and cover are glued in a single operation, then trimmed to size. Both sources note that perfect binding is simpler and faster gfsmn.comphotobookpress.com. This efficiency makes it ideal for urgent print runs or projects with tight deadlines.

At Lion Paper Products we operate advanced binding equipment, including automatic laminators and spiral and perfect binding machines. Our production capacity allows us to scale quickly and meet deadlines, whether you choose lay‑flat or perfect binding. To schedule a production timeline tailored to your order size and location, please contact our manufacturing team for a personalized plan.

Environmental and sustainability considerations

Modern buyers increasingly value sustainability in manufacturing. The choice of binding can influence the environmental footprint of your notebooks. Lay‑flat binding uses PUR adhesive, which is more durable and typically applied in smaller quantities than EVA. Printivity notes that PUR binding applies a thinner coating, reducing material use while enhancing flexibility printivity.com. Because PUR‑bound books last longer and resist heat, cold and moisture, they may have a lower environmental impact over their lifespan; you won’t need to replace them as often.

Perfect binding using EVA glue is less environmentally friendly because EVA adhesives may soften under heat and are not as resistant to oils and chemical sprintivity.com. However, EVA is widely recyclable, and many printers now offer eco‑friendly EVA formulations. When comparing binding options, consider the entire lifecycle of the product: durability, recyclability and the energy required for production.

At Lion Paper Products we prioritise sustainability; our factories meet ISO 9001 and environmental standards, and we continually invest in efficient machinery to reduce energy consumption. Contact us if you would like to learn more about our commitment to environmentally responsible binding solutions.

When should you choose lay‑flat binding?

Lay‑flat binding is the premium choice when you need a high‑end presentation and want your notebook or book to make an immediate impression. Here are common scenarios where lay‑flat binding excels:

Photo and art books: Photographers, designers and artists benefit from seamless spreads and accurate colour reproduction.

Luxury notebooks and journals: Brands seeking a distinctive user experience appreciate the 180‑degree opening and durability.

Lookbooks and catalogues: Fashion and product catalogues often use lay‑flat binding to showcase full‑bleed images without gutter loss.

Portfolios and presentations: Architects and creative professionals rely on the lay‑flat format to display detailed plans and artwork.

If your project fits any of these categories, consider investing in lay‑flat binding. Our sample makers can quickly produce prototypes so you can see the effect for yourself. Send an inquiry and we’ll help you evaluate paper options, covers and finishing to achieve the perfect look.

When should you choose perfect binding?

Perfect binding remains the industry standard for soft‑cover books because it offers a balance of cost, durability and professional appearance. Opt for perfect binding when:

Novels and manuals: Long‑form texts benefit from the clean spine and efficient production.

Magazines and catalogues: For large print runs where cost per unit is critical, perfect binding delivers value.

Corporate reports: Annual reports, training manuals and guides require a professional look without the higher cost of lay‑flat binding.

Light to moderate use: If the book won’t be opened flat repeatedly, perfect binding provides adequate durability.

Our experience with large retailers, e‑commerce sellers and government institutions shows that perfect binding can meet demanding quality standards at scale. If you’re unsure which binding fits your needs, reach out to us for a consultation; we can send samples and cost comparisons to help you decide.

How Lion Paper Products can help

Choosing between lay‑flat and perfect binding involves balancing performance, budget, design and timeline. At Lion Paper Products we have over 10 years of experience serving stationery buyers in the United States, United Kingdom, Germany, Spain, Australia, Singapore, Qatar and South Africa. We operate factories in China and Cambodia and partner with facilities in South Korea to offer flexible production options. Our investment in automated binding machines, visual positioning instruments and quality control systems ensures consistent quality across both lay‑flat and perfect bound notebooks.

Our R&D team provides cover layout tuning and sample production within 5–7 working days. We hold ISO9001, FAMA, California Proposition 65, CPSIA and European environmental certifications, and our factories adhere to BSCI human rights standards. With a professional sales team based in Jiaxing and more than ten years’ exporting experience, we guide you through the entire procurement process from design to delivery. Whether you need 1,000 custom planners with lay‑flat binding or 20,000 perfect bound journals, our capacity and expertise will save you time and ensure satisfaction.

—Leo Xia, CEO, Lion Paper Products

You design, we deliver.

FAQs:

Q1: What is the main difference between lay‑flat binding and perfect binding?

A: Lay‑flat books use a free‑floating spine and flexible PUR adhesive so pages open 180 degrees and lie flat without warping. Perfect binding glues the pages directly to the cover, giving a square spine but restricting the book from opening fully.

Q2: Which binding method is more durable?

A: Lay‑flat binding is generally more durable because PUR adhesive creates a stronger, flexible bond and the pages aren’t stressed when opened; the GFS article notes that pages stay together over time. Perfect binding can be durable if PUR glue is used, but EVA glue is less flexible and may crack with repeated use.

Q3: Why does lay‑flat binding cost more?

A: The process requires precision alignment of signatures, special paper, reinforced hinges and manual binding. Both GFS and PhotoBook Press remark that lay‑flat binding’s superior quality comes at a higher cost.

Q4: How many pages can a lay‑flat book have?

A: Lay‑flat binding supports a wide range of page counts and can go up to about 200 pages.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition!

Comments