What is Silk Screen Printing

- Lion Paper Team

- Aug 4, 2025

- 3 min read

Quick Content Reach:

Silk screen printing, also known as screen printing or serigraphy, is one of the oldest and most reliable printing techniques used globally. It is highly effective for achieving bold, durable, and vivid designs on a wide variety of surfaces—especially in the custom stationery industry. Whether you’re sourcing notebooks, planners, or journals, understanding this method can help you ensure your product line stands out.

1. The Process of Silk Screen Printing

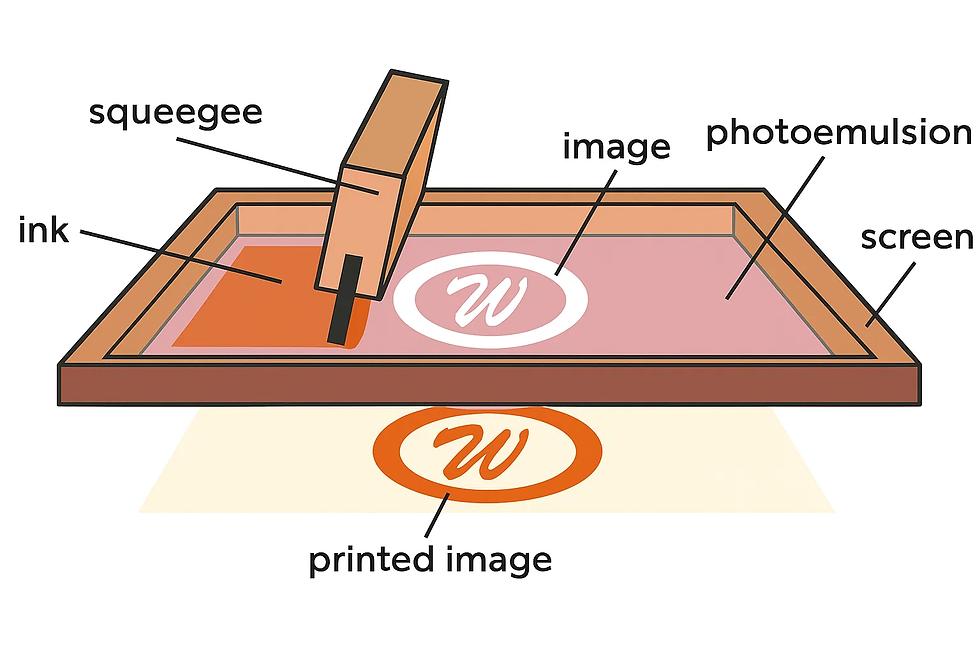

Silk screen printing involves pushing ink through a mesh screen that has a stencil blocking certain areas. The open mesh areas allow ink to pass through and form the desired image on the substrate—commonly paper, plastic, or fabric.

Step-by-Step:

Design Creation – The desired design is separated by color and transferred to film.

Screen Preparation – A mesh screen (polyester or stainless steel) is coated with light-sensitive emulsion.

Exposure – The film and screen are exposed to UV light to harden the emulsion.

Washing Out – Unhardened areas are washed away, leaving a stencil.

Printing – Ink is pushed across the screen using a squeegee.

Curing – The printed product is dried or heat-cured for permanence.

For precise multi-color and brand-specific artwork, our sample production team ensures high-quality results within 5–7 days.

2. Key Components

Understanding the components ensures better production decisions, particularly for bulk stationery orders.

Main Elements:

Screen: Made of polyester or stainless steel, used to hold the stencil.

Stencil: Blocks parts of the screen, forming the desired pattern.

Ink: Can be water-based, solvent-based, or UV-curable depending on application.

Squeegee: Rubber tool that forces ink through the screen evenly.

Substrate: The material to be printed on (paper, cardboard, plastic, etc.).

Contact us today to explore how our silk screen printing capabilities can elevate your brand’s stationery line.

3. Applications of Silk Screen Printing

Silk screen printing offers flexibility across multiple materials and industries, making it ideal for diverse stationery product lines.

。

Common Applications:

Custom Notebooks: Logos, patterns, and textures printed on covers or pages.

Gift Bags: Brand-specific visuals enhance shelf appeal.

Calendars: Allows for vibrant month-by-month color designs.

Packaging: Premium textures and finishes stand out to consumers.

Retail Branding: Signage and promotional material.

Planning to diversify your stationery portfolio? Silk screen printing adds visual richness that differentiates your brand.

4. Advantages of Silk Screen Printing

This printing method offers long-lasting, high-resolution results ideal for brand-focused stationery.

Why Choose Silk Screen Printing?

Durability: Ink adheres strongly and resists fading.

Vibrancy: Produces bold, saturated colors.

Versatility: Compatible with a wide range of materials.

Scalability: Cost-efficient for high-volume production.

Texture: Adds tactile richness to covers and packaging.

Looking for durable branding on your stationery products? Silk screen printing delivers results that last.

Conclusion

Silk screen printing combines tradition with innovation, making it a powerful tool for custom stationery manufacturers. It’s reliable, scalable, and vibrant—traits essential for making a brand’s identity unforgettable.

Let’s discuss how Lion Paper Products can help you use silk screen printing to enhance your stationery line.

FAQs:

Q1: What is silk screen printing used for?

A: It’s widely used in textiles, paper goods, packaging, and promotional products.

Q2: Is silk screen printing eco-friendly?

A: Water-based inks and sustainable screens can make it environmentally responsible.

Q3: Can silk screen printing be used on paper products?

A: Yes, especially for notebooks, journals, and packaging.

Q4: What’s the best material for screen printing?

A: Paper, plastic, fabric, metal, and even wood.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition!

Comments