Lion Paper's Quality Control: Carton Package Drop Testing

- Lion Paper Team

- Jul 7, 2025

- 4 min read

Quick Content Reach:

Why Carton Package Drop Testing Matters

At Lion Paper, quality control is an integral part of our production process, and it extends beyond just the product itself. One of the most crucial aspects of ensuring product safety during transportation is testing the durability of the packaging. Carton package drop testing is a vital procedure we use to ensure that our products arrive at their destination safely, without damage. This test simulates the rough handling that packages often undergo during transit, allowing us to assess the integrity of our packaging and make necessary adjustments.

What is Carton Package Drop Testing?

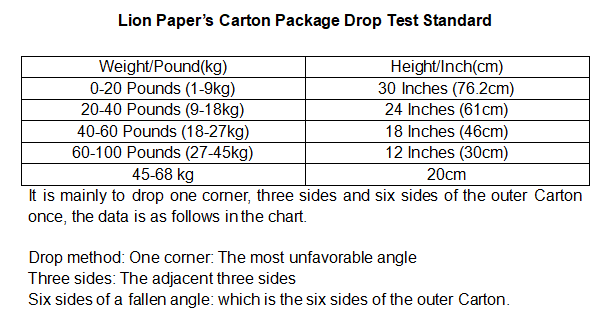

Carton package drop testing involves dropping a package from a specific height onto a hard surface to simulate the impact that occurs during handling and transportation. This test helps evaluate whether the packaging materials and design can withstand the physical stresses associated with shipping. The test is typically conducted on different sides of the carton to assess how each side responds to the impact.

Why Does Lion Paper Use Drop Testing?

Lion Paper places great emphasis on the protection of our products, especially during their journey from factory to customer. The goal of drop testing is to ensure that our products are packed in a way that minimizes the risk of damage while they are being transported. By conducting drop tests, we can identify potential weaknesses in packaging and improve the design to prevent damage to the contents, ultimately ensuring customer satisfaction.

The Process of Carton Package Drop Testing

The process begins by preparing the package in its final shipping form, with the actual product inside. The carton is placed on a test platform, and the package is dropped from a specified height, typically ranging from 30 cm to 1.5 meters, depending on the product's shipping conditions. The package is then inspected for any visible damage or deformation. The test is repeated several times, with the carton being dropped onto different sides, edges, and corners to ensure a thorough evaluation.

Key Benefits of Carton Package Drop Testing

Product Protection: By simulating the rough handling products often experience, drop testing helps ensure that the packaging offers sufficient protection for the product inside.

Improved Packaging Design: Drop testing reveals weak points in packaging, allowing us to improve the design for better performance during shipping.

Cost Savings: By reducing damage during shipping, drop testing can help minimize the costs associated with returns and replacements.

Increased Customer Satisfaction: When products arrive in perfect condition, it leads to higher customer satisfaction and repeat business.

Lion Paper’s Commitment to Quality Control

At Lion Paper, we take pride in our rigorous quality control measures. From raw material selection to final packaging, every step of our production process is carefully monitored. Carton package drop testing is one of the many tests we conduct to ensure that our products arrive in perfect condition. We understand that packaging plays a vital role in the overall customer experience, and we are committed to continually improving our methods to deliver the best possible products.

Conclusion: Ensuring Quality Every Step of the Way

Lion Paper’s commitment to quality doesn’t stop at the product itself—it extends to every aspect of the production and shipping process. Our carton package drop testing is just one example of how we prioritize product protection and customer satisfaction. By constantly testing and improving our packaging, we ensure that our products arrive safely, providing our customers with the best possible experience.

FAQs:

Q1: What is carton package drop testing?

A: Carton package drop testing simulates the impact during handling and shipping by dropping a package from a specified height to assess the packaging's durability.

Q2: Why is carton package drop testing important?

A: It ensures that the packaging can protect the product from damage during transit, reducing the risk of returns and improving customer satisfaction.

Q3: How does Lion Paper conduct drop testing?

A: We drop the package from a specified height multiple times onto different sides to assess its durability and performance.

Q4: What are the benefits of drop testing?

A: It improves packaging design, protects products, saves costs, and enhances customer satisfaction by ensuring products arrive undamaged.

Q5: Can drop testing be applied to all types of products?

A: Yes, drop testing can be applied to a wide range of products, especially those that will be transported in cartons.

Q6: What happens if a product fails drop testing?

A: If a product fails, we redesign the packaging and conduct further tests until the packaging meets our durability standards.

Q7: How does drop testing impact the final product?

A: It ensures that the product is safe for transport and arrives in perfect condition, minimizing any risks of damage during shipment.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition.

Comments