How Lion Paper Ensures Quality from the Start: Raw Material Inspection Explained

- Leo Xia

- Jun 24, 2025

- 3 min read

Updated: Jun 26, 2025

Quick Content Reach:

Why Raw Material Quality Is Non-Negotiable

In the world of custom notebook manufacturing, high-end buyers know that quality isn’t built in the final product stage—it begins at the source. That’s why at Lion Paper Products, we don’t leave raw material quality to chance. From premium acid-free paper to durable PU covers and metal coil bindings, our raw material inspection process is the first line of defense against product defects, compliance risks, and customer dissatisfaction.

Our mission is simple: deliver durable, stylish, and compliant paper goods that uphold your brand. But how exactly do we do it? Here's a full breakdown.

1. Goods Reception and Traceability

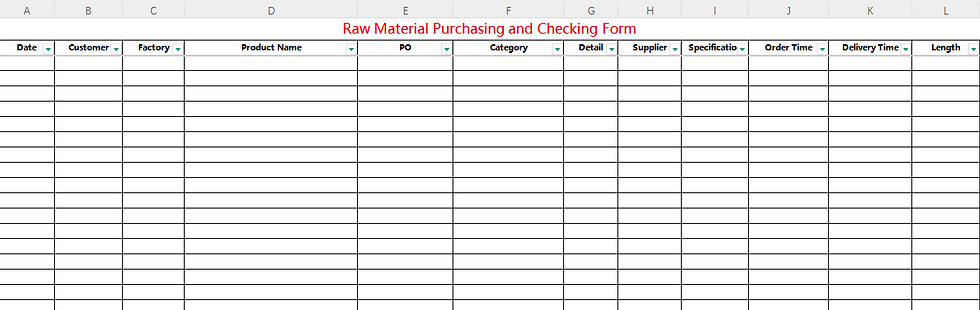

Every raw material shipment arriving at our factory undergoes registration:

Supplier Info: name, batch number, delivery date

Quantity & Specs: against the Purchase Order (PO)

Traceability: All materials are digitally logged and assigned traceable digital files that follow the production lifecycle.

2. Visual Inspection of Incoming Materials

Our trained QC team checks for visible defects. Each material has its own criteria:

Paper: no stains, creases, tears, discoloration

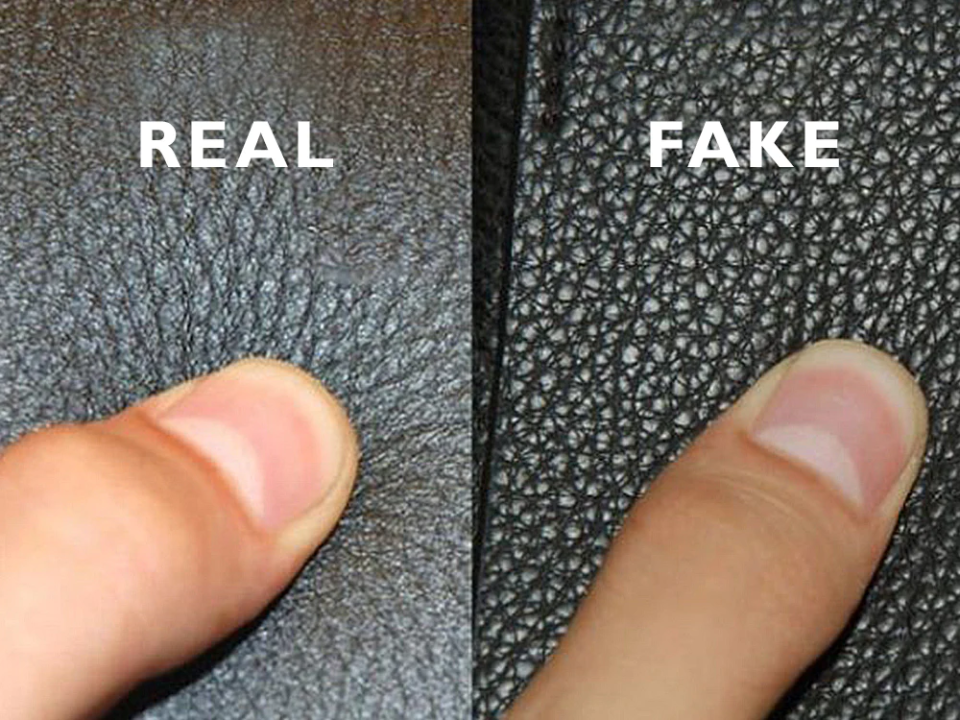

Covers (PU/leather/fabric...): no warping, color deviation, scratches

Accessories (elastic bands, bookmark ribbons, coils): must meet size, color, and tension requirements

3. Material Property Testing

For Paper:

GSM testing: measured with digital micrometers

Opacity/bleed-through test: ensure no ghosting with pen/ink

Stiffness test: using Taber or similar devices

pH balance check: acid-free guarantee

For Cover Materials:

Abrasion resistance: using Martindale or rotary rub test

Water resistance: partial immersion tests

Tensile strength: stretch-resistance testing

For Coils:

RoHS & anti-rust compliance: verified through XRF testing

Elasticity test: ensures coils can hold pages securely without deformation

4. Compliance & Safety Testing

To serve markets like the U.S. and EU, Lion Paper performs third-party compliance tests on all raw materials:

Heavy metals: lead, cadmium (EN71-3, CPSIA)

Phthalates (plasticizers): REACH, Prop 65

Formaldehyde release: for adhesives or fabrics

5. Sample Archiving & Non-Conformance Protocol

Each batch undergoes sample archiving:

Retained samples stored for traceability and testing review

Non-conforming batches flagged, isolated, and held

Supplier feedback mechanism and re-audit of high-risk vendors

Conclusion: Quality Starts Before Production Begins

At Lion Paper, we’ve always believed that exceptional notebooks begin long before the first page is printed. Our raw material inspection process forms the cornerstone of our commitment to you: ensuring every custom notebook, planner, journal, or calendar we produce meets your highest standards.

Whether you’re sourcing for a major retail campaign or a boutique brand, Lion Paper guarantees transparency, compliance, and craftsmanship in every batch we receive.

Let’s build quality from the very beginning.

—Leo Xia, CEO, Lion Paper Products

FAQs:

Q1: What raw materials are tested at Lion Paper?

A: Lion Paper tests paper, cover materials, metal coils, glues, and accessories.

Q2: Do you provide third-party compliance reports?

A: Yes. Reports from SGS, BV, Intertek can be supplied.

Q3: What happens if a material batch fails inspection?

A: It is isolated, returned, or replaced.

Q4: What regulations do your materials meet?

A: CPSIA, CA Prop 65, EN71, REACH, ISO9001... We can do tests as required.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition.

Comments