Silk Screen Printing: How It Works in Notebook Manufacturing

- Lion Paper Team

- Aug 5, 2025

- 5 min read

Updated: Sep 12, 2025

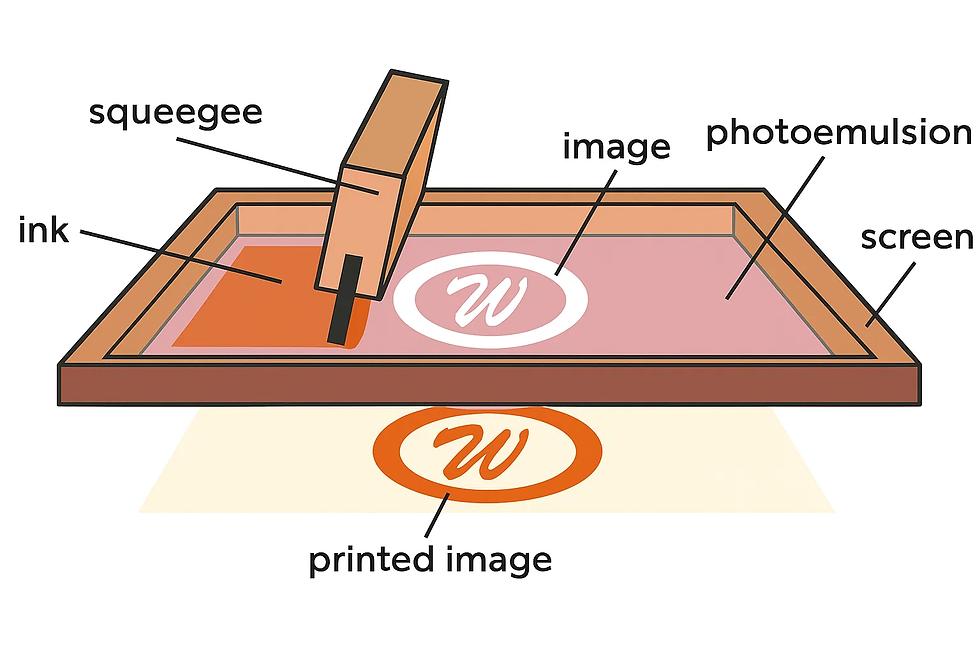

To screen print a notebook, a stencil of the design is created on a mesh screen, which then acts as a template. The screen is placed on the notebook, ink is applied to the screen, and a squeegee is used to push the ink through the mesh and onto the notebook's cover or inside page. The process is repeated for each color in the design, with the stencil and ink matching the original artwork, and the final print is then dried to cure the ink.

Quick Content Reach:

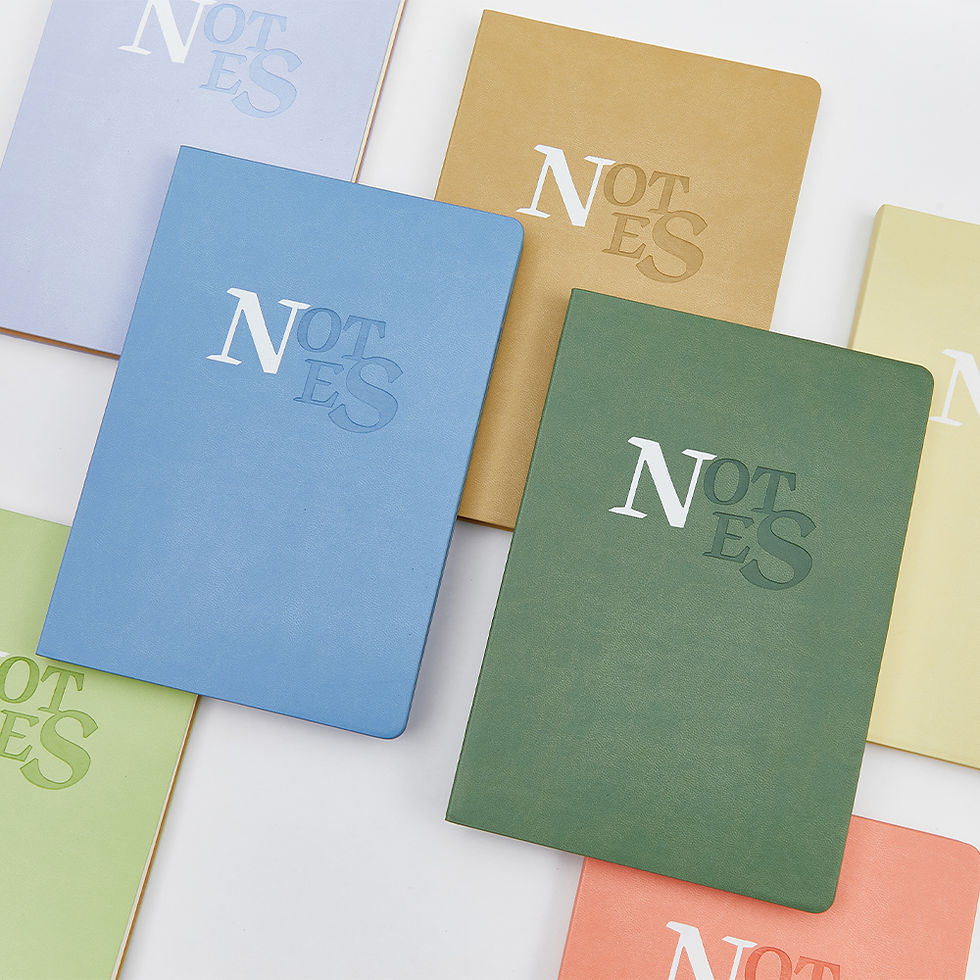

Silk screen printing, often simply called screen printing, is a classic, reliable printing technique known for its bold, vibrant outputs. In the notebook manufacturing, silk screen printing is used to imprint covers with logos, brand names, and customized designs. Whether you're a stationery buyer sourcing for chain stores or an e-commerce operator looking for brand consistency, understanding this method can help you make informed decisions.

At Lion Paper Products, we use silk screen printing to enhance notebook branding and personalize covers to suit your unique brand identity. Contact us today to discuss your printing needs or request a sample.

How Silk Screen Printing Works in Notebook Production

1. Design Creation

The process begins with your custom design. This could be a company logo, tagline, pattern, or artwork. The design is digitally separated by color and printed on a transparent film to act as the basis of the stencil.

Why it matters: A clean design translates into a clean print.

2. Screen Preparation

A fine mesh screen (traditionally made of silk, but now more commonly polyester) is tightly stretched over a metal or wooden frame. This screen is then coated with a light-sensitive emulsion.

Why it matters: The tension and coating quality directly affect image clarity and ink distribution.

3. Stencil Creation

The transparent film is placed over the screen, which is then exposed to UV light. Light hardens the emulsion on areas not covered by the design. Unexposed emulsion is washed away, leaving behind a stencil.

Why it matters: This step determines where ink will pass through. Accurate stencils ensure brand precision and reduce waste.

4. Printing

The notebook cover is placed under the prepared screen. Ink is applied on top of the screen and forced through the open stencil areas using a squeegee. Each color requires its own screen.

Why it matters: The even application of ink guarantees uniform branding.

5. Drying and Finishing

Printed covers are set aside to dry. Some inks require heat curing, especially metallic or UV-resistant types. Finishing may involve lamination or additional treatments to enhance longevity.

Why it matters: Drying ensures print durability.

Need weather-proof or water-resistant covers? Inquire now about our recommendations.

Advantages of Silk Screen Printing for Notebooks

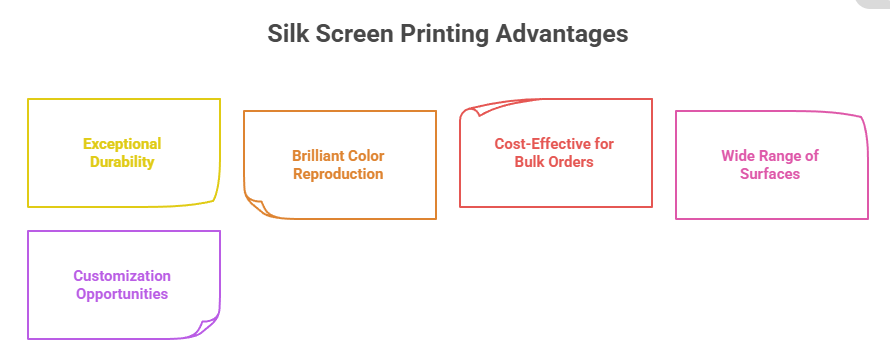

Exceptional Durability

Unlike digital prints that may fade or scratch, silk screen prints penetrate the surface, making them highly resistant to wear and tear.

Brilliant Color Reproduction

Silk screen excels at solid colors and creates deep, saturated tones even on dark materials. It accommodates specialty inks such as metallics, fluorescents, and glow-in-the-dark.

Cost-Effective for Bulk Orders

Although the initial setup is labor-intensive, silk screen printing becomes cost-effective at scale. This makes it a prime choice for wholesale buyers and bulk promotional notebooks.

Wide Range of Surfaces

Silk screen works on PU leather, paperboard, fabric, plastic, and even wood. It offers unmatched versatility for custom notebook applications.

Customization Opportunities

You can adjust ink opacity, layer multiple effects, or use foils in tandem with screen printing. That means endless design potential for private label stationery lines.

Want help preparing your artwork for printing? Contact us now for a free consultation and professional advice.

Disadvantages of Silk Screen Printing for Notebooks

Higher Initial Setup Costs

Stencil creation, screen coating, and setup all require time and skilled labor. For low-volume runs, this can inflate your cost-per-unit.

Solution: For small batches, we may suggest digital or offset printing as a more cost-effective alternative.

Limitations with Fine Detail

Silk screen struggles with intricate details or photographic elements. The mesh can only capture a certain resolution.

Tip: Use this method for logos, shapes, and bold typography—save fine gradients or photographic art for digital methods.

Time-Consuming for Small Runs

The setup involved means turnaround times are longer for short production runs.

Workaround: Our 10+ production lines can handle staggered orders, which speeds up production even for mid-sized batches.

When to Choose Silk Screen Printing for Your Notebooks

Ideal Use Cases:

Promotional notebooks for trade shows

School and corporate branding

Retail stationery with minimalist designs

Notebooks requiring vibrant colors on dark covers

Products needing waterproof or UV-resistant ink

When to Reconsider:

Very small print runs (<500 units)

Complex, multi-color photo images

Projects with fast turnarounds under 5 days

Need help matching your project to the right method? Let our experts assist you.

Why Work With Lion Paper Products

10+ years of notebook, stationery, gift bags manufacturing and exporting

Full-stack customization: paper weight, cover texture, binding method

Direct access to printing, packaging, and logistics experts

In-house R&D and sample team

Responsive English-speaking consultants

Let’s co-create the next stationery hit. Send your project brief now.

Comparison Table: Silk Screen vs Digital Printing

Feature | Silk Screen Printing | Digital Printing |

Best Use Case | Bulk orders, bold logos & solid designs | Small batches, photo-realistic designs |

Setup Time | High | Low |

Color Range | Limited per screen, solid colors best | Full color (CMYK), gradient friendly |

Detail Handling | Moderate (not for fine detail or images) | Excellent (sharp detail, small text/images) |

Material Compatibility | Very wide (fabric, PU, kraft, etc.) | Mostly paper and coated materials |

Cost Effectiveness | Better for large volumes | Better for short runs |

Turnaround Time | 7–10 days | 2–5 days |

Eco-Friendliness | Available with water-based inks | Less environmentally friendly in large runs |

FAQs:

Q1: What is silk screen printing?

A: Silk screen printing is a technique where ink is pushed through a mesh screen to create designs on notebook covers.

Q2: Is silk screen printing waterproof?

A: Yes, depending on the ink used, the prints can be waterproof.

Q3: What materials can I print on?

A: PU leather, kraft paper, plastic, fabric, and more.

Q4: How many colors can I use?

A: Each color requires a separate screen. Simple designs with 1–3 colors are ideal.

Q5: Is silk screen better than digital printing?

A: It depends on your project needs—screen is better for bulk, digital for short runs.

Q6: Do you offer sample prints?

A: Yes, we can send samples within 5–7 working days.

Q7: Can you match Pantone colors?

A: Yes, we offer Pantone color matching.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition!

Comments