High-quality Notebook Printing: 6 Major Types

- Leo Xia

- Nov 10, 2025

- 10 min read

Updated: Nov 10, 2025

Professional notebook printing is more than just ink on paper. It covers concept development, selection of sustainable papers and covers, meticulous pre‑press preparation, high‑precision printing, the right binding method and rigorous quality control. Understanding each step helps custom notebook printing buyers compare suppliers, avoid costly reprints and ensure their brand image is faithfully reproduced. This guide explains how to make notebooks that stand out.

Quick Content Reach:

6 Steps of High‑Quality Notebook Printing

Modern notebook printing follows six tightly integrated stages. First the design is refined so every page fits the chosen binding. Next the materials are selected—paper weight, page ruling and cover stock—based on durability and branding. Pre‑press technicians then prepare print files with proper margins, color profiles and imposition to ensure accurate reproduction. During printing, advanced offset or digital presses lay down ink consistently for sharp text and vibrant images. Afterward, sheets are cut and bound using methods such as saddle‑stitching, perfect binding with PUR adhesives, spiral coil or case binding. Finally, quality control inspections check color, binding strength and alignment before the finished notebooks are packaged for delivery.

Looking for a reliable notebook printing partner? Contact us now to get your project started.

Step 1 – Artwork Fine‑Tuning and Design

Quality begins with design. Buyers should provide press‑ready files or collaborate with experienced designers who understand print production. Programs like Adobe InDesign are preferred because they control bleeds, margins and imposition. Pre‑press experts recommend at least 0.125 inch bleeds to ensure artwork extends to the edge of the page and 0.5 inch margins to keep text from being cut off. Fonts must be embedded or outlined, images should be at least 300 dpi and pages must be set up in the correct sequence.

Choose page size and layout based on how the notebook will be used. A5 notebooks (approximately 5.8 × 8.3 inches) are a popular balance between portability and writing space; A4 (8.3 × 11.7 inches) suits planners and sketchbooks; A6 (4.1 × 5.8 inches) fits pockets. Decide whether pages will be ruled, dotted or blank to match the customer’s writing style. At Lion Paper Products we offer bespoke layouts including monthly calendars, dot‑grid bullet journaling and task trackers. You can also specify numbered pages, perforations, index sections, pen loops or elastic closures.

Cover design also matters. Options range from soft‑touch coated cardstock to PU leather covers, kraft board or premium fabrics. Creative touches like foil stamping, debossing, die‑cut windows or custom artwork give a notebook personality. The design stage is when branding elements—company logos, slogans and Pantone colors—are finalized. Effective collaboration between your in‑house team and our designers helps ensure the finished product tells your brand story.

Step 2 – Material Selection

Selecting the right materials affects the notebook’s feel, durability and sustainability. Start with the inner paper.

Paper weight: Paper weight is measured in grams per square metre (GSM). Light weights (80–90 gsm) work well for everyday writing; heavier stocks (120–140 gsm) resist bleed‑through and are preferred for sketching or markers. Medium‑weight papers (170–216 gsm) allow embossing and spot UV finishes, while heavy card stocks over 250 gsm are used for covers. Choosing the right paper weight prevents ghosting and ensures pages lay flat.

Paper type: Select lined, dotted or blank pages depending on the notebook’s purpose. Dotted grids help bullet journal users maintain neat layouts; lined pages suit diaries and meeting notes; blank pages are ideal for sketchbooks. For color printing, choose a coated paper with smooth finish; uncoated stock provides a natural feel.

Sustainable options: Eco‑minded buyers should consider FSC‑certified or recycled paper. FSC certification ensures the paper originates from responsibly managed forests and tracks the supply chain to verify sustainable practices. Recycled paper reduces deforestation and greenhouse gas emissions. Synthetic paper made from plastics resists water and tearing and eliminates the need for lamination.

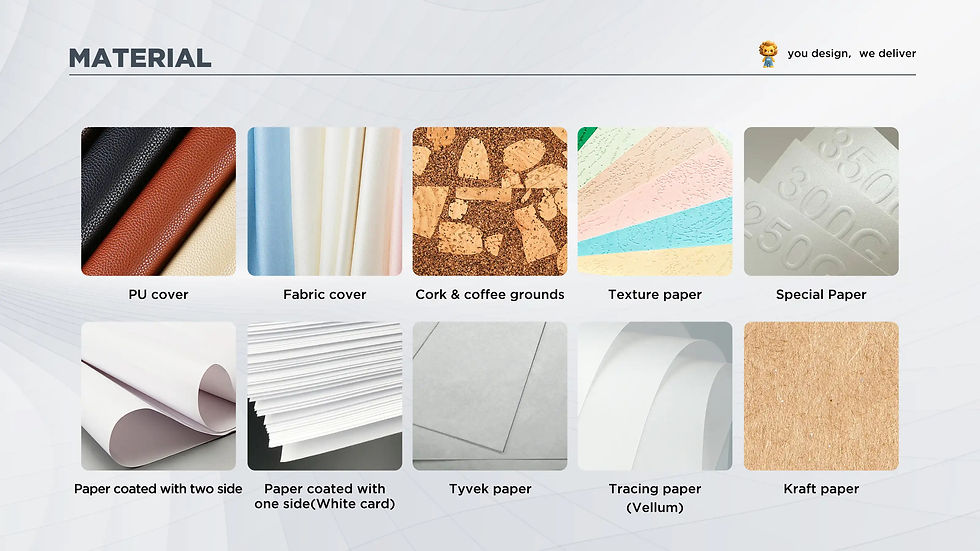

Cover materials: Softcover notebooks use flexible cardstock; hardcover or casebound notebooks use dense board wrapped with cloth, kraft or leatherette. PU leather offers a luxurious look, while kraft paper conveys sustainability. A lay‑flat journal uses Smyth‑sewn binding (sections are stitched together with thread), which provides durability and pages that open flat. For cost‑effective bulk orders, perfect binding with PUR adhesive is popular.

Finishes: Lamination or coating protects the cover and adds tactile interest. Gloss lamination is shiny and repels fingerprints, making colors pop. Matte lamination has a velvety feel and resists scratches; it pairs well with spot UV where selected elements receive a high‑gloss treatment for contrast. Soft‑touch lamination creates a luxurious suede‑like texture. UV coatings cure quickly, resist scratches and fading, and can be applied as spot gloss accents. Think about how the notebook will be used—daily, promotional or gifting—and choose a finish that enhances its appeal.

Step 3 – Pre‑Press and File Preparation

Pre‑press is the hidden hero of custom notebook printing. This stage ensures that what you see on screen is faithfully reproduced in print. Preflight checks verify that fonts are embedded, images are high resolution, colors are set to CMYK, bleed and trim lines are correct and pages are imposed in the right order. Designers must convert RGB images to CMYK and set up spot colors if Pantone matching is required.

A digital or physical proof is created so you can check color accuracy, layout and binding marks before full production begins. This proofing stage is essential for catching errors early; if needed, adjust the artwork and resubmit. Good communication between buyer and pre‑press technician speeds up approvals and reduces waste.

Another pre‑press decision is whether to print using CMYK process or Pantone spot colors. CMYK combines cyan, magenta, yellow and black inks to produce a wide color gamut at low cost. However, some vibrant hues and corporate colors are difficult to match precisely. The Pantone Matching System uses pre‑mixed inks to achieve exact color fidelity; it’s ideal when brand consistency is critical but costs more printingsolutions.com. Our team will advise you on the best option for your project and budget.

Step 4 – Printing

Once files are approved, the actual printing begins. Two main technologies are used in notebook printing: offset and digital.

Offset printing: For large‑volume runs (hundreds or thousands of notebooks), offset presses deliver superior color consistency and efficiency. Each color requires a separate plate; the ink is transferred (offset) from plate to blanket to paper. Offset printing supports high resolutions and special inks like metallics or spot UV. It’s the industry standard for corporate branded notebooks and large promotional orders.

Digital printing: For small quantities or personalized notebooks, digital printing offers quick setup and lower costs. Digital presses print directly from a digital file without plates, making them ideal for custom variations or on‑demand orders. Advances in digital inks allow vibrant colors and near‑offset quality, though per‑unit costs can be higher for long runs.

During printing, ensure color profiles are calibrated and that high‑quality inks are used to prevent fading or smudging. If your design uses metallic foils or spot UV accents, those finishes are applied after the base print. Discuss with us whether your order should combine digital and offset methods to optimize cost and quality.

After printing, large sheets are cut down to final size. Precision cutting is crucial to ensure uniform edges and proper bleed. Next comes binding, which determines how the notebook opens, lies flat and endures daily use. Major binding types include:

Saddle stitching: Pages are folded and stapled along the spine. This cost‑effective method is perfect for slim notebooks or brochures, allows pages to lay flat and is ideal for smaller page counts.

Perfect binding: Pages are gathered, the spine edge is roughened and glued to a wraparound cover. Perfect binding offers a professional look and can accommodate higher page counts. Traditional perfect binding uses EVA hot‑melt glue, but many printers now prefer PUR (polyurethane reactive) adhesive because it forms bonds up to 50 % stronger and more flexible than EVA printivity.com. PUR handles coated and recycled papers, resists extreme temperatures, and provides better lay‑flat performance. It’s an excellent choice for custom printed notebooks that must withstand heavy use.

Spiral or coil binding: Holes are punched along the edge and a plastic or metal coil is inserted. Spiral binding allows pages to fold back 360 degrees and lay flat. It’s popular for planners, calendars and notebooks that need to stay open on a desk. Wire‑O binding uses double loops for increased durability and a more upscale appearance.

Case (hardcover) binding: Also called casebound, this method glues or sews pages into a rigid cover. Hardcovers provide superior durability and a premium feel. For luxury journals, Smyth‑sewn binding stitches sections together with thread, ensuring pages can open flat without breaking the spine. This lay‑flat characteristic makes Smyth‑sewn books prized by artists and note‑takers.

Lay‑flat (section‑sewn) binding: Sections are sewn through the fold and glued to a cover. The book opens completely flat, making it ideal for sketchbooks and presentation notebooks.

The final finishing steps include trimming edges for a clean look, rounding corners to prevent wear, adding elastic bands or pen loops, and applying decorative embellishments like metallic foils, debossing, embossing or die‑cut shapes. Coatings such as gloss, matte, soft‑touch, UV, varnish or lamination are applied to protect the cover and add tactile interest. Spot UV can highlight a logo or artwork by adding a shiny layer on a matte background. Soft‑touch lamination provides a luxurious velvet feel. When selecting finishing, consider how your notebook will be handled—coated covers withstand heavy use, while uncoated covers offer a natural, eco‑friendly feel.

Explore binding options like PUR, spiral, and sewn. Leave an inquiry to compare samples and pricing.

Step 6 – Quality Control and Packaging

Quality control ensures that every notebook leaving the factory meets your standards. Rigorous checks should occur before, during and after production. Pre‑press inspection verifies file formats, resolution, color modes and imposition. During printing, press operators calibrate color profiles to maintain consistent reproduction. After binding, inspectors examine alignment, trimming and cover adhesion, perform page‑pull strength tests and check that materials meet specifications. The industry references ISO, NASTA and LBI standards to ensure durability and longevity.

Environmental and social responsibility are increasingly important to buyers. Many customers request FSC, PEFC or recycled paper; look for suppliers who carry these certifications. At Lion Paper Products we also undergo amfori BSCI audits to ensure our factories protect workers’ rights, provide fair remuneration and maintain safe working conditions. The BSCI Code of Conduct covers freedom of association, non‑discrimination, fair remuneration, reasonable working hours and workplace health and safety. Participating in BSCI audits enhances our reputation, improves relationships with suppliers and helps avoid negative press.

Once notebooks pass inspection, they are packaged to protect them during transit. Options include shrink wrapping, paper bands, tissue wrapping, custom boxes or retail‑ready packaging. For large shipments, we offer palletization and export cartons. Clear labelling and barcodes streamline inventory management for wholesalers and retailers. Buyers should also consider drop‑shipping or distribution services if they sell through e‑commerce channels.

Buyer’s Checking List

Selecting the right notebook printing service requires due diligence. Use this checklist to evaluate suppliers and ensure your investment delivers quality and value:

Define purpose and quantity: Are you ordering promotional journals, corporate gifts, retail products or event giveaways? Estimate your volume to determine whether offset or digital printing is most cost‑effective.

Confirm design readiness: Provide press‑ready files with appropriate bleed, margins and embedded fonts. Ask for templates if you need guidance.

Assess material options: Review paper weights, page rulings and cover materials. Request samples of FSC‑certified, recycled or synthetic paper.

Discuss binding types: Choose from saddle‑stitched, perfect bound (EVA or PUR), spiral/coil, Wire‑O, casebound or Smyth‑sewn depending on page count and budget. Ask about PUR adhesives for durability.

Specify finishes: Decide whether you need lamination (gloss, matte, soft‑touch), spot UV, foil, embossing or debossing. Finishes enhance appearance and protect the notebook.

Confirm color requirements: Determine whether CMYK printing is sufficient or if Pantone matching is needed for brand colors.

Review certification and sustainability: Ensure the factory holds ISO9001 quality management certification, FSC chain‑of‑custody and amfori BSCI audits tuvsud.com. Ask about environmental tests (e.g., California Prop 65, CPSIA) if selling in regulated markets.

Request proofs and samples: Insist on digital or physical proofs before production. Check binding strength and finish quality.

Understand lead time and logistics: Clarify production time, shipping options, customs documentation and whether the supplier offers drop‑shipping or fulfilment services.

Communication and support: Choose a partner who provides responsive communication, clear documentation and post‑sale support. A dedicated project manager can save you time and prevent costly errors.

Final Words

Producing high‑quality notebooks is a craft that combines design, materials, technology and quality control. Whether you’re creating corporate branded notebooks, promotional giveaways or retail journals, understanding the six steps of custom notebook printing empowers you to make informed decisions and avoid common pitfalls. As a B2B buyer, you need more than an ordinary printer—you need a partner who understands your brand, offers flexible options and adheres to international standards.

Lion Paper Products has invested heavily in advanced equipment, from Heidelberg presses and automatic spiral binders to laser die‑cutting machines. Our quality management team performs 100 % inspections using video‑recorded processes, and our factories are certified to ISO9001, FSC, SEDEX SMETA and amfori BSCI standards. We offer a full sample service, fast prototyping in 5–7 days, and end‑to‑end solutions—from concept and packaging to display design.

—Leo Xia, CEO, Lion Paper Products

You design, we deliver.

FAQs:

Q1: What binding method is best for corporate branded notebooks?

A: For professional appearance and durability, PUR perfect binding or Smyth‑sewn case binding are ideal. PUR provides a strong, flexible spine, while Smyth‑sewn books lay completely flat.

Q2: What paper weight should I select for a notebook?

A: For everyday writing, 80–90 gsm paper works well. For sketchbooks or fountain‑pen‑friendly notebooks, choose 120–140 gsm. Heavier covers use 250–350 gsm card stock.

Q3: What eco‑friendly options are available for notebook printing?

A: Choose FSC‑certified paper to ensure responsible sourcing, recycled paper to reduce deforestation and emissions, or synthetic paper that is waterproof and tear‑resistant.

Q4: Why should I work with a BSCI‑certified supplier?

A: Amfori BSCI audits ensure suppliers respect workers’ rights, provide fair remuneration and maintain safe working conditions. Working with certified factories reduces reputational risk and demonstrates corporate social responsibility.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition!

About Lion Paper

Company Name: Lion Paper Products

Office Address: 20th floor, Chuangyedasha Building, No. 135, Jinsui Road, Jiaxing City, Zhejiang Province, China

Factory Address: No.135, Xuri Road, Jiaxing City, Zhejiang, China

Email: Leoxia@lion-paper.com

Audit Certifications: ISO9001:2015/FSC/SEDEX SMETA/Disney FAMA/GSV/SQP

Comments