How Final Quality Checks Protect Every Notebook?

- Lion Paper Team

- Jul 4, 2025

- 4 min read

Updated: Jan 23

Quick Content Reach:

The Importance of Final Quality Checks

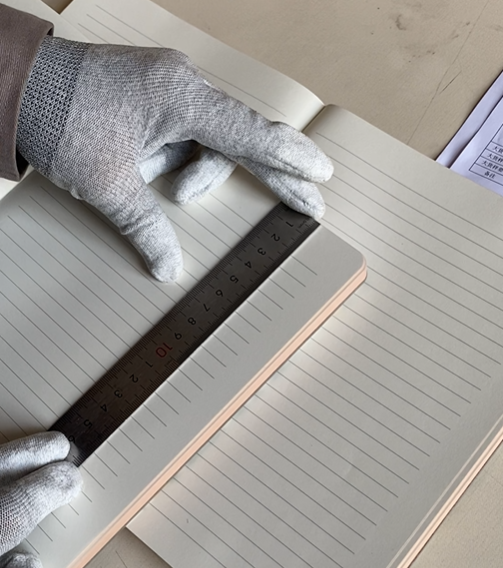

Final quality checks are the last line of defense in notebook production, ensuring that every product is up to standard before it reaches the consumer. From ensuring that the binding is secure to checking for imperfections in the paper, final quality checks help identify and address issues that may affect the performance or aesthetic of the notebooks.

In this article, we will explore the critical role of final quality checks in notebook production, focusing on how they protect both the product and the brand. Understanding these checks will give you insight into how notebook manufacturers ensure the best possible outcomes for every batch.

1. Why Final Quality Checks Matter

The importance of final quality checks cannot be overstated. These checks are conducted when the product is nearly finished—often between 30% to 50% of the production is completed—and right before packaging. They are crucial in identifying potential flaws that can impact a notebook's functionality, appearance, or overall quality.

A comprehensive final quality check includes a thorough inspection of:

Paper Quality: Ensuring there is no bleeding, discoloration, or rough texture.

Binding Integrity: Verifying that the binding is secure and that pages are properly aligned.

Cover and Print Quality: Checking that the design is consistent, with no misprints or defects.

Finishing Touches: Ensuring the corners are rounded, the edges are clean, and the overall finish is smooth.

By conducting these checks, manufacturers can guarantee that customers receive a top-quality notebook, and that returns due to defects are minimized.

2. How Final Quality Checks Prevent Common Defects

Many issues in notebook production can be traced back to the finishing stages. Without thorough quality checks, problems like poor binding, paper warping, and ink smudging can go unnoticed. Here's how final quality checks prevent these common defects:

Paper Defects

During production, various paper defects can occur—such as poor folding, misalignment of printed pages, or paper irregularities like spots or tears. Final quality checks ensure that only pristine paper makes it into the final product.

Binding Problems

Notebooks with weak bindings or improperly aligned pages can fall apart quickly. Final quality checks include testing the durability of the binding and confirming that the pages are securely fastened, preventing issues like loose pages or weak spines.

Printing and Cover Design

Even with high-quality paper, the visual appeal of a notebook matters. During the final quality checks, manufacturers examine the covers for flaws in design, color accuracy, and print clarity. This ensures that logos, titles, and designs appear as intended.

3. Final Quality Checks in the Production Process

Final quality checks are conducted at the completion of most of the notebook's production process, when 80% of the work is done and the product is nearing its packaging phase. Here’s a breakdown of what happens at each stage of the final check:

Stage 1: 30%-50% Completion

At this stage, the notebook’s binding is usually complete, and the pages are assembled. Quality inspectors check the alignment of the pages, ensuring that they are in the correct order and bound securely.

Stage 2: 80% Completion, Before Packaging

Before the notebooks are packaged, the final quality checks ensure that every detail is correct. This includes checking for color consistency, proper labeling, and any signs of wear or damage during production. Any defective notebooks are flagged and removed from the batch, ensuring that only the best products make it to the consumer.

4. Benefits of Effective Final Quality Checks

Improved Customer Satisfaction

By eliminating defects before they reach customers, final quality checks help ensure that the consumer receives a product that meets their expectations. A high-quality notebook enhances the user experience and builds brand loyalty.

Reduced Returns and Complaints

Effective quality checks reduce the chances of returns due to defects. This helps manufacturers avoid the financial losses and reputational damage associated with dissatisfied customers.

Enhanced Brand Reputation

Consistency is key to maintaining a strong brand reputation. When customers can rely on the consistent quality of a product, they are more likely to return for future purchases and recommend the brand to others.

Conclusion: Protecting Your Product and Brand Through Final Quality Checks

Final quality checks are an essential part of notebook production that help protect both the product and the brand. By ensuring that each notebook is free from defects and meets the highest standards, manufacturers can guarantee a positive experience for customers and reduce the risk of returns.

With our QC system, thorough inspections, and careful attention to detail, final quality checks offer a powerful defense against defects, helping to deliver top-quality products that reflect the brand’s commitment to excellence.

FAQs:

Q1: What are final quality checks in notebook production?

A: Final quality checks are the last step in the notebook production process to ensure the product is free from defects and meets the required standards.

Q2: Why are final quality checks important?

A: They ensure that the final product is of high quality, reducing defects and improving customer satisfaction.

Q3: What types of defects are checked during final quality checks?

A: Paper defects, binding issues, cover design flaws, and printing errors are all checked during final quality control.

Q4: How do final quality checks improve customer satisfaction?

A: By ensuring products are defect-free, final quality checks prevent disappointment, enhancing the customer experience.

Q5: What is the best time in production for final quality checks?

A: Final quality checks are usually done when 80% of the production is completed, just before packaging.

Q6: How can I ensure my notebooks are quality-checked effectively?

A: Partner with manufacturers who have strict quality control standards and utilize both manual and automated checks throughout production.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition.

Comments