A Comprehensive Guide: Custom Belly Band for Notebook Packaging

- Leo Xia

- Oct 13, 2025

- 8 min read

Updated: Oct 23, 2025

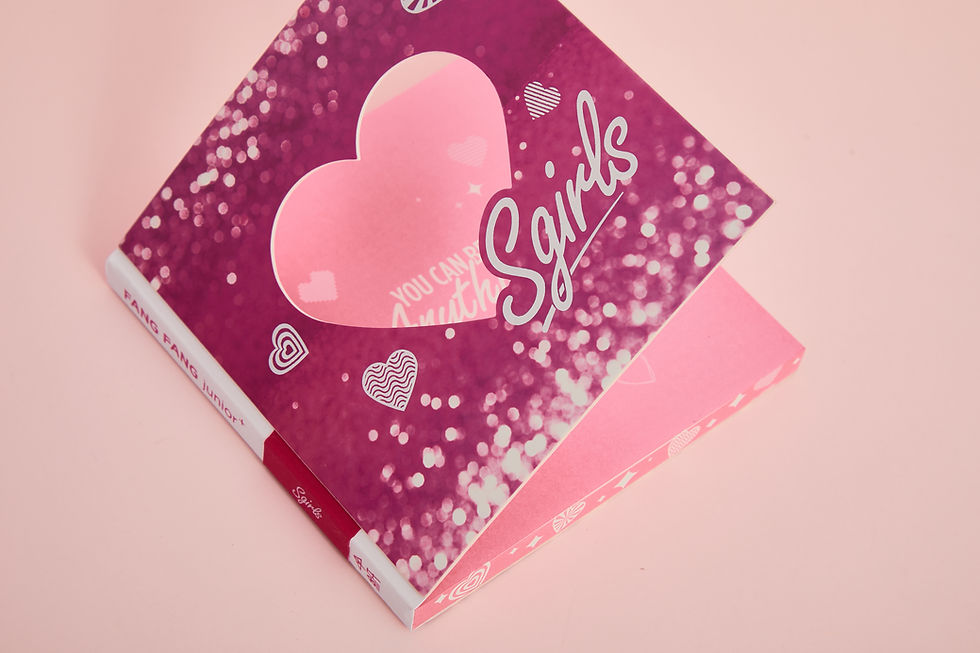

Custom belly band is a removable wrap that encircles a notebook to carry branding, specs, barcodes, and messaging. For custom notebook packaging, it elevates shelf appeal, protects in transit, and adds a premium unboxing touch. The right paper, finish, and size tolerance make custom belly bands both beautiful and practical.

Quick Content Reach:

What’s Belly Band and Its Purpose

A belly band is a printed wrap—usually paper or film—that goes around the center of a notebook, journal, or set. Unlike shrink-wrap, it’s tactile, reusable, and easy to remove without residue. In belly bands packaging, it acts as a mini billboard: highlighting features, paper weight, page count, sustainability claims, and brand story.

Core purposes

Branding: front-facing space for logo, collection name, tagline, and key specs.

Information: barcode, SKU, care or recycling marks, legal lines.

Protection: helps keep covers closed and accessories together during handling.

Retail readiness: consistent look across SKUs for planograms and quick scanning.

Sizing basics (quick guide)

Measure notebook circumference at the wrap position (include cover thickness).

Add 6–10 mm overlap for gluing or adhesive dots.

Set ±1–2 mm tolerance for paper “spring-back.”

Confirm placement against elastic bands, pen loops, or metal corners.

Benefits of Custom Belly Band for Branding

A well-designed custom belly band for notebook packaging can lift conversions online and in stores.

Why it works

Instant positioning: Distills the brand promise and main benefits on first glance.

Storytelling: Space for origin, eco materials, FSC labels, or creator notes.

Cross-sell: Promote matching pens, stickers, or planner refills.

Seasonal agility: Update bands (not the core product) to run campaigns or collabs.

Cost-effective: Lower cost than full box packaging; high ROI per unit.

Visual rules of thumb

Prioritize logo, product name, and one key benefit above the fold.

Keep barcode area clear; reserve high-contrast space per retailer spec.

Use finishes to create hierarchy (e.g., foil for logo, Spot UV for keywords).

Where Belly Bands Are Used

Belly band printing offers excellent branding opportunities for notebooks, planners, and journals. These bands wrap around the books, displaying intricate messages or colorful designs not possible on the product itself. Experts highlight that bands allow for unique branding, product details, or matching designs. Foiling effects add luxury, while uncoated paper offers a tactile feel. They also assist in identifying journal contents through spine printing.

Spotlight paper specs (GSM, ruling), page count, binding, and special inserts.

Ideal for custom notebook packaging bundles (notebook + pen + stickers).

Packaging Boxes

Custom printed belly bands elevate ordinary boxes to high-end packaging by encircling folding carton, rigid, and magnetic closure boxes. They enhance branding, visual appeal, and prevent accidental opening. Eco-conscious brands can upgrade packaging without redesigning current boxes.

Minimalist rigid or kraft boxes elevated by a branded wrap; easy to localize via band swaps.

Cards & Envelops

Paper belly band packaging elevates the presentation of cards, especially for weddings, corporate events, and special occasions. These decorative features bring elegance and sophistication to mailings while also providing practical benefits. The bands keep multiple items—like invitation cards, directions, or extra information—neatly bundled together. This guarantees that recipients receive all components as intended, with everything staying intact.

Tie greeting card sets together; print themes, quantity, and price neatly on the band.

Product Packaging

Belly wrap prints are versatile and enhance various products like food containers, soaps, electronics, candles, cosmetics, and clothing. Custom belly bands are ideal for items with generic packaging or those not needing full packaging, providing a cohesive look across product lines with different containers, helping customers identify related products.

Wrap lifestyle goods (planner refills, stationery kits, mini albums) for a cohesive shelf look.

Provide us with your product list and retail channels, and we'll suggest the optimal belly bands packaging strategy for each SKU and channel (DTC vs. wholesale).

Printing Finishes for Custom Belly Bands

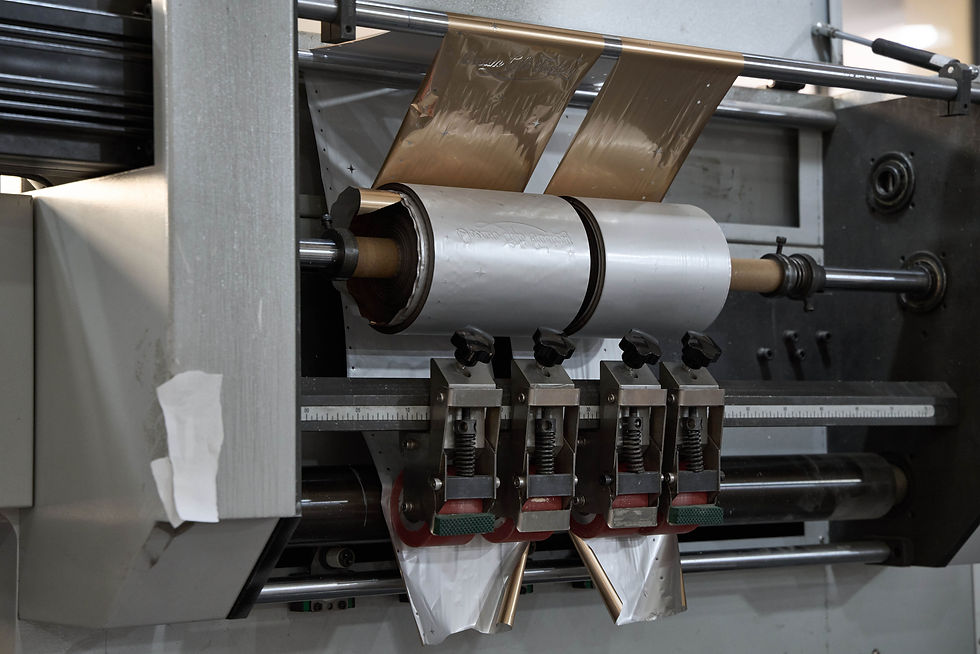

Lamination

Lamination protects belly bands and enhances their appearance. Glossy lamination intensifies colors with a reflective surface, ideal for bold graphics or vivid photography. Matte lamination provides a non-reflective, smooth finish, offering a sophisticated look and improving text readability by reducing glare.

Soft-touch lamination, also known as velvet lamination, is the most tactile choice available. It creates a suede-like texture that enriches color depth and gives your custom printed belly bands a luxurious sensation. The high quality is noticeable by touch, making it perfect for premium products.

Gloss: vivid, high contrast, fingerprint-resistant.

Matte: elegant, low glare; pairs well with Spot UV.

Soft-touch: velvety handfeel; premium perception.

Foil Stamping

Applying heat-applied metallic foil to belly wrap prints creates vibrant accents that enhance packaging appeal. Gold, silver, and rose gold foils make belly bands more noticeable, often highlighting logos, titles, text, or graphics.

Metallic or pigment foils to highlight logos and headline claims; great for gifting lines.

Spot UV

Spot UV applies a glossy coating to specific areas of custom belly bands, creating visual and tactile contrast by elevating these sections. This technique highlights key design elements like logos or intricate patterns, especially against dark backgrounds.

Glossy accents over matte bases to pull attention to key words or patterns.

Embossing

Embossing adds raised designs to belly band packaging, allowing customers to engage with your brand through its distinctive texture, leaving a lasting impression before they view the contents.

Raised texture for logos or motifs; enhances tactile brand memory.

Die Cut

Die cutting extends beyond traditional rectangles, creating unique contours, windows, and decorative edges for distinctive packaging. It reflects brand identity through functional elements like tabs or slots and decorative features. Precise die lines ensure accurate production of custom die-cut belly bands.

Windows to preview covers/textures; shaped edges; easy-tear notches.

Share your logo and budget—we’ll propose three finish stacks (Core / Premium / Luxe) with cost and impact comparison for custom belly bands.

Paper Types for Custom Belly Band

Coated One Side Paper (C1S)

Smooth print surface; good stiffness; ideal for strong color and crisp type.

Art Paper (Coated)

Gloss or matte; excellent image reproduction; common weights 128–250 gsm.

Uncoated Paper

Natural look, writable; suits earthy brands and minimal aesthetics.

Kraft Paper

Brown or bleached; sustainable vibe; pairs well with black ink or white foil.

Recycled Paper

Eco messaging alignment; verify FSC or recycled content where required.

Vellum Paper (Translucent)

See-through layer to tease cover design; elegant for special editions.

Selection tips

Match paper weight to band width and notebook thickness to avoid curling.

Consider crack-resistant stocks for heavy emboss or spine curves.

If moisture risk exists, add lamination or water-resistant coating.

Designing Custom Belly Bands

Choosing Right Size and Shape

Standard straight wrap vs. shaped edges; keep corners robust to prevent dog-ears.

Allow space for glue tab or double-sided tape dots; avoid placing text on seam.

Adding Logo, Text and Graphics

One hierarchy per panel: Logo → Product name → Key benefit → Specs → Barcode.

Use icons for specs (GSM, ruling, recycled, page count) to reduce text load.

Selecting Color and Fonts

High contrast for barcode zone; ensure AAA contrast for tiny legal lines.

Limit to 2–3 brand fonts; pair display type with legible sans for small copy.

Calibrate color for coated vs. uncoated stocks; soft-touch slightly mutes saturation.

Send your brand kit—we’ll build a grid-based layout that locks spacing, type scale, and barcode quiet zones for every custom belly band size.

Tips For Custom Belly Bands Design

Paying attention to technical details is crucial for custom belly band printing. Adhering to specifications ensures professional results and prevents delays, making sure your belly bands match your vision.

Leave 3mm Bleed

A proper bleed setup is essential for professional belly band printing. Extend your design by 3mm on all sides to avoid white edges after trimming. This margin accounts for cutting variations, ensuring a smooth design. Any elements reaching the edge should extend into the bleed area to prevent unwanted white lines due to misalignments.

Extend backgrounds and images; prevent white slivers at trim.

Use High Quality Image

To achieve sharp and clear prints, utilize images with a minimum of 300 DPI. Although images might look acceptable on a screen, low resolution can result in blurry and pixelated prints. Beginning with high-quality images guarantees superior print quality and saves time.

300 dpi at final size; avoid upscaling; embed or package links before export.

Leave 5mm Safe Zone

Make sure that all text, logos, and essential graphics are positioned within a 5mm safety margin from the trim edge to preserve crucial design elements. Certain printers might need a 3mm buffer to account for trimming variations and protect important information.

Keep text/logos clear of trim, folds, and glue area; protect scannability.

Save in Correct File Format

Select the appropriate file format to ensure the best print quality and efficiency. PDFs are perfect for belly band designs as they maintain the layout. For precise print colors, use a CMYK color profile. High-resolution JPG, TIFF, or packaged AI files with embedded fonts are also appropriate choices.

Convert spot colors as needed; outline fonts or package with profiles; include dieline layer.

Pre-press checklist

CMYK profile noted (e.g., FOGRA/GRACoL).

Overprint settings verified (especially black text on foil).

Dieline as spot color, non-printing in final export.

Not sure your files are print-safe? Email us the artwork—we’ll run a free pre-flight and return press-ready PDFs for custom belly band for notebook packaging.

Final Words

A custom belly band is one of the fastest, most economical ways to elevate custom notebook packaging. It carries brand story, communicates specs, and drives retail clarity—without re-engineering your core product. Choose the right paper, size tolerance, and finish stack to balance cost and impact. Standardize a dieline and typographic system to scale across SKUs and seasons with minimal effort.

Ready to upgrade your line? Contact us at Leoxia@lion-paper.com or WhatsApp +86 137 5075 6354. We’ll design, prototype, and produce custom belly bands that convert—backed by fast sampling (5–7 days), strict QC, and global fulfillment.

—Leo Xia, CEO, Lion Paper Products

You design, we deliver.

FAQs:

Q1: What is a custom belly band?

A: A removable printed wrap around notebooks or other products for branding, specs, and protection.

Q2: How do I measure the correct size?

A: Measure circumference at wrap line, add 6–10 mm overlap, and allow ±1–2 mm tolerance.

Q3: Which paper weight works best?

A: Commonly 128–250 gsm; thicker bands suit thick notebooks or wide wraps.

Q4: What finishes improve shelf impact?

A: Soft-touch, foil stamping, Spot UV, emboss/deboss, and window die-cuts.

Q5: Can belly bands be eco-friendly?

A: Yes—use FSC/recycled stocks, plant-based inks, and water-based coatings.

Q6: What adhesion method is recommended?

A: Glue tab or double-sided tape dots; choose based on paper and finishing.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition!

About Lion Paper

Company Name: Lion Paper Products

Office Address: 20th floor, Chuangyedasha Building, No. 135, Jinsui Road, Jiaxing City, Zhejiang Province, China

Factory Address: No.135, Xuri Road, Jiaxing City, Zhejiang, China

Email: Leoxia@lion-paper.com

Audit Certifications: ISO9001:2015/FSC/SEDEX SMETA/Disney FAMA/GSV/SQP

Comments