How Our Cambodia Factory Is Raising the Bar on Quality Assurance Standards

- Leo Xia

- Jul 28, 2025

- 4 min read

Quick Content Reach:

1. How Our Cambodia Factory Is Raising the Bar on Quality Assurance Standards

When your notebooks are bound for premium shelves in the U.S. or high-volume distributors in Germany, "close enough" isn’t good enough.That’s why I, Leo Xia, CEO of Lion Paper Products, personally led the transformation of our Cambodia factory's quality control system. Our goal? To raise the bar from basic inspection to audit-compliant, globally trusted, customer-centric quality assurance.

This is not just a story of checklists and process flows—it’s about culture, commitment, and capability. If you’re a sourcing manager, product director, or CEO looking for a dependable and globally compliant partner in stationery manufacturing, this article will offer practical insight. And yes, feel free to contact us or message me on WhatsApp if you’re evaluating new suppliers.

2. From Patchwork to Process: The Old Quality Control Reality

When we first assessed the Cambodia factory’s QC system, we saw passion but lacked structure:

Basic documents existed (e.g., initial inspection flow, non-conformance forms)

QC staff had documented some common issues (e.g., misaligned punches, bad foil blocking)

Some preventative mindset had emerged (e.g., SOPs for debris removal post-hole punching)

However, problems included:

Fragmented documentation not forming a closed loop

SOP training inconsistencies leading to repeat errors

Poor adaptation to local language and operator experience

Higher risk of inconsistencies, especially on complex orders. We knew that wasn't acceptable.

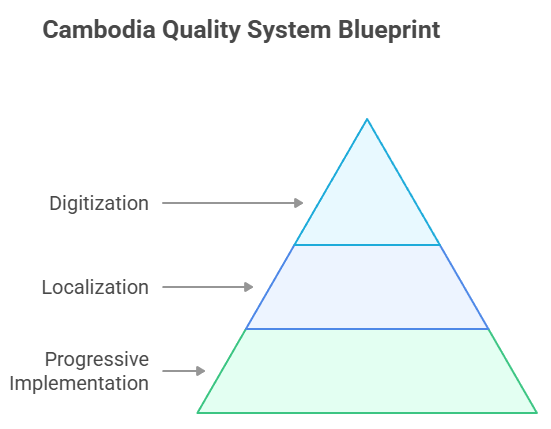

3. The Turnaround Blueprint: 3 Guiding Principles

Our new quality system for Cambodia is based on three operational pillars:

Progressive Implementation: From execution-level to audit-level maturity, in three phases

Localization: All documents are bilingual (Chinese-Khmer) with >60% visual content

Digitization: Shared digital documents solve traceability and access issues

These aren’t theory—they are embedded in every step we now take. Want to see our real bilingual SOPs? Request a sample.

4. Rebuilding the Core: A System of Integrated Quality Documents

1. Quality Manual (Excerpt)

Quality Policy: “Process-driven, prevention-focused, continuous improvement, customer satisfaction.”

Every task must be supported by an SOP; no guesswork

Key defect rate (PPM) goal: below 50 (based on 82 PPM baseline)

Monthly QC review chaired by the Cambodia Factory Manager

2. Work Instructions for Patrol Inspection

Inspection frequency:

Key processes (e.g., punching, casing-in): every 2 hours

General processes (e.g., folding, packaging): every 4 hours

New staff: +30% inspection frequency for 3 days

Example checklist for wire-o notebook:

Cover tolerance: ±0.5mm (measured with calipers)

Foil test: must pass 3M tape pull without flaking

Coil tolerance: ±0.2mm; bend >1mm = reject

3. Non-Conformance Handling Procedure

Red label = scrap

Yellow label = rework (group leader approval if ≤3 defects)

Blue label = special approval (requires client confirmation)

Why it matters: Structured systems protect your brand reputation. Let’s walk through how our processes align with your QC requirements.

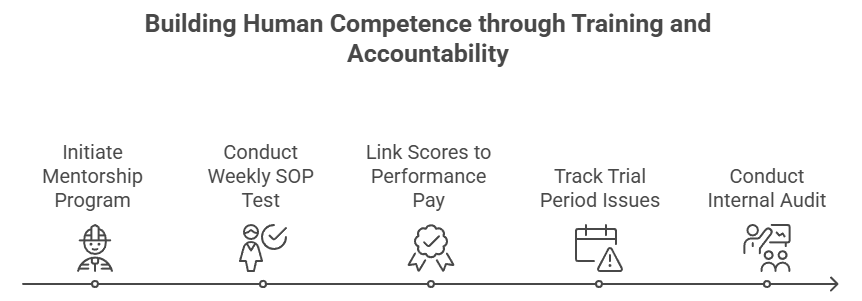

5. Training & Accountability: Building Human Competence

Technology and processes only work if people understand them.

"1+1 mentorship": One Chinese technician mentors 3 Cambodian workers

Weekly SOP test: Every Wednesday, scores tied to performance pay

Trial period tracking: Weekly issue log during pilot month (August), internal audit in September

6. Audit-Ready from Day One

Global buyers often ask: "Will your factory pass FSC or SMETA or GSV, etc audits?"

Now the answer is: Yes! And we will add the audits as our clients asked.

CAPA (Corrective and Preventive Action) plans are embedded in reports

Traceability systems include defect cause logs, root-cause video reviews

Monthly review meetings are chaired by the Cambodia GM and documented

If you’re preparing for your next audit, we’re ready to support you with compliant documentation.

7. Digital-First Quality Management

No more paper-only logs:

All forms are digitized and stored in a shared cloud environment

Each defect entry includes timestamp, photo

Result: Faster responses, cleaner data, and real-time client transparency. Contact us to preview our dashboard.

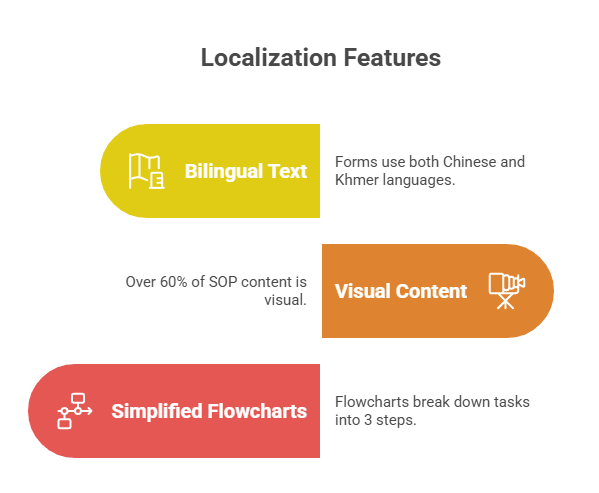

8. Localization Done Right: Designed for the Cambodian Workforce

We recognized early on that SOPs must match the skill levels of operators:

All forms use bilingual Chinese-Khmer text

Over 60% of SOP content is visual (photos, diagrams, checklists)

Flowcharts break down each QC task into no more than 3 steps

Final Word: Better Systems, Better Products, Better Partnerships

The Cambodia factory is no longer just a secondary production base. It’s a flagship of how regional operations can meet world-class quality.

From enhanced documentation to smarter inspections, from local empowerment to global compliance—we built this with you in mind.

Let’s co-create your next best-selling product line, with precision and pride.

Email our professional sales, Lily@lion-paper.com or message +86 13750756354 to begin.

—Leo Xia, CEO, Lion Paper Products

You design, we deliver.

FAQs:

Q1: What quality system does your Cambodia factory follow?

A: We follow a process-driven, prevention-first QC system based on ISO principles.

Q2: How do you handle quality defects?

A: We classify them (scrap/rework/special approval) and track via digital logs.

Q3: How do you train new workers?

A: Through mentorship, SOP exams, and extra QC during their first 3 days.

Q4: How often are internal audits conducted?

A: Every month, with a detailed follow-up action plan.

Q5: Do you collect defect trend data?

A: Yes, we analyze recurring issues for continuous improvement.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition!

Comments