How to Choose the Right Paper Thickness for Your Custom Notebook?

- Leo Xia

- Jun 8, 2025

- 4 min read

Updated: Jun 12, 2025

Quick Content Reach:

Why Paper Thickness Matters More Than You Think

Whether you're sourcing planners for a premium retail line or customizing journals for your brand, paper thickness—often measured in GSM (grams per square meter)—plays a silent but critical role in the user experience.

Too thin, and ink bleeds through. Too thick, and the notebook becomes bulky and expensive. This guide walks you through how to choose the right paper thickness for your custom notebook—balancing quality, aesthetics, cost, and brand positioning.

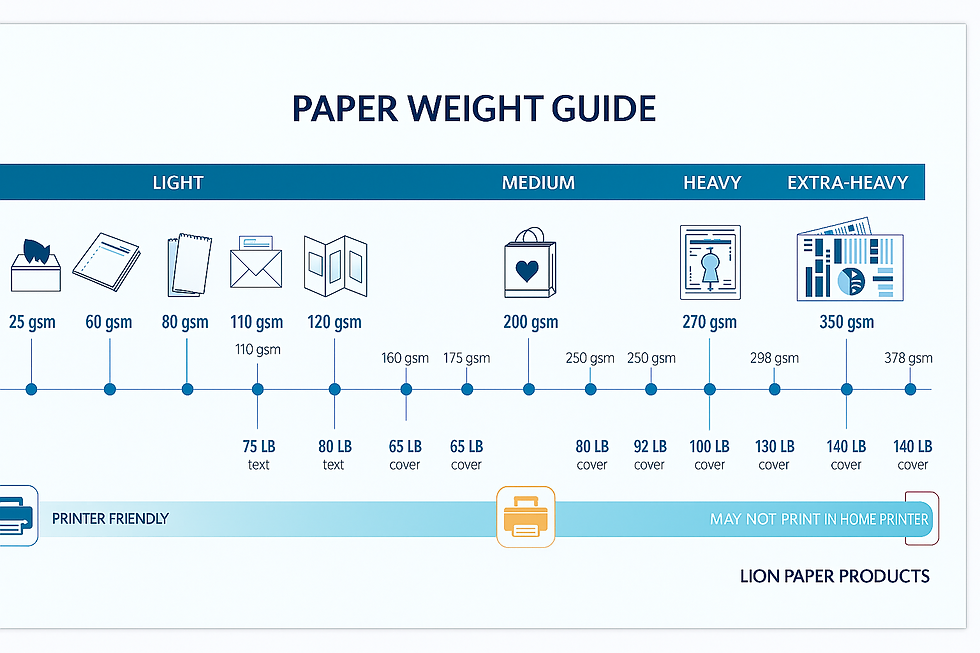

What Is GSM? (And Why It’s Crucial in Notebooks)

GSM (grams per square meter) refers to the weight of paper. It’s not the thickness per se, but it gives a reliable indication of how sturdy or translucent the paper will feel.

For example:

70–90 GSM: Light and smooth, often used for basic writing or mass-market notebooks.

100–120 GSM: Common for premium notebooks; it reduces bleed-through for gel pens or fountain pens.

130–170 GSM: Ideal for sketching, dual-sided printing, or artistic journals.

200+ GSM: More like cardstock; best for dividers, covers, or scrapbooking inserts.

💡 Tip: Heavier GSM paper is not always better. Consider your target customer and intended use.

Understand Your Audience and Product Purpose

Choosing the right GSM starts with understanding who will use the notebook and how. Here’s how GSM aligns with use cases:

Intended Use | Recommended GSM Range | Why It Works |

Office Writing | 80–100 GSM | Lightweight, easy to flip pages, good for ballpoint pens |

Student Journals | 70–90 GSM | Cost-effective, especially for bulk school orders |

Premium Planners | 100–120 GSM | Offers a smooth surface for gel/fountain pens |

Artistic Sketchbooks | 130–160 GSM | Prevents ink and marker bleed-through |

Cover Pages | 250–300 GSM | Durable and supports foil stamping or embossing |

Paper Thickness vs. Paper Quality—Not the Same Thing

It’s a common misconception: heavier paper = better paper. Not always true.

A 100 GSM recycled paper may have more texture and ink resistance than a 120 GSM low-grade sheet.

Coated vs. uncoated: Coated papers (e.g., matte or gloss) feel smoother but are less absorbent.

Acid-free options prevent yellowing and appeal to archival or long-term users.

📌 Pro Tip: Always test print with your ink type and binding method.

Matching Paper Thickness With Binding Styles

Binding style can also influence your GSM choice:

Binding Type | Recommended GSM | Considerations |

Saddle Stitch | ≤100 GSM | Avoid thick paper; pages will not fold well |

Perfect Binding | 80–120 GSM | Works well for books with higher page counts |

Spiral/Coil Binding | 70–160 GSM | Very flexible; popular for mixed-use notebooks |

Casebound/Hardcover | 100–130 GSM | Ideal for executive planners and gift journals |

🧠 Insight: We once produced a 300-page wire-o notebook with 100 GSM FSC-certified paper and a kraft board cover—balancing bulk and eco-appeal for a European client.

GSM and Your Brand Positioning

Paper thickness is part of your brand’s tactile story. Here’s how to align it:

Luxury Brands: Use 100–130 GSM smooth white paper with foil edges and rounded corners.

Eco Brands: Try 80–100 GSM recycled paper with unbleached tones.

Educational Publishers: Opt for 70–90 GSM cost-effective paper with good erasure resistance.

Each choice reflects your identity. GSM is not just technical—it’s emotional.

Factors That Affect GSM Selection (Beyond Just Cost)

Ink CompatibilityMatch GSM to your customers’ likely writing tools. Gel pens? Go heavier.

Page CountMore pages? Use lower GSM to avoid a bulky book.

Environmental ComplianceEco-conscious clients prefer FSC-certified or recycled GSM options.

Print TechniquesEmbossing, stamping, and full-bleed images need thicker paper for impact.

Don't Skip Sampling: Why We Insist on Print Tests

At Lion Paper, we never skip the sample phase. Here’s what we recommend before mass production:

Blank Paper Samples: Feel, fold, and write on various GSM samples.

Printed Dummies: Assess ink bleed-through, ghosting, and drying time.

Bound Samples: See how the thickness affects the notebook’s spine and usability.

📷 Bonus: All our sampling is done on production-line machines—not lab printers—so what you see is what your customer gets.

Let Paper Weight Tell Your Brand Story

Choosing the right paper thickness is a blend of science, strategy, and storytelling. It influences user comfort, brand impression, and your overall cost structure. Don’t just go with what your competitor uses—opt for what fits your customer’s habits and your brand’s purpose.

—Leo Xia, CEO, Lion Paper Products

FAQs:

Q1: Can 80 GSM support fountain pens?

A: Only for low-bleed inks. For guaranteed performance, we suggest 100 GSM or higher.

Q2: What GSM is best for double-sided printing?

A: Minimum 100 GSM. Anything lighter may ghost or curl.

Q3: Will heavier GSM delay production?

A: Not necessarily—but it may limit your binding options and increase shipping cost.

Q4: What’s the best GSM for eco-conscious brands?

A: Recycled paper between 80–100 GSM with FSC/PEFC certifications is a great balance.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition.

Comments