How Are Die-Cut Notebooks Made?

- Leo Xia

- Jul 10, 2025

- 3 min read

Updated: Jul 13, 2025

Quick Content Reach:

Why Die-Cut Notebooks Matter to Stationery Buyers

As a professional manufacturer of notebooks and stationery, some of my clients place orders for Die-Cut Notebooks with us annually, and these orders represent a significant portion of our overall custom orders. Why do they favor this type of notebook so much? After gathering information and discussing with my clients, I have some insights.

In the competitive world of stationery, standing out matters. Die-cut notebooks do just that—offering intricate shapes, unique silhouettes, and unforgettable tactile experiences that traditional notebooks can't match. For professional B2B buyers, retailers, and brand managers, understanding how die-cut notebooks are made isn't just a curiosity—it's essential to making informed sourcing decisions and crafting memorable customer experiences.

What Is a Die-Cut Notebook?

A die-cut notebook is a notebook with custom-shaped elements created using a steel cutting tool called a "die." This technique is widely used for shaping covers, inner pages, tabs, or window cutouts with high precision. In 2025, advanced die-cutting equipment allows for greater detail, better consistency, and faster production speeds than ever before. In the following steps, I'll provide a brief introduction to the production process, and I hope you find it helpful.

Step 1: Die Creation

Every die-cut notebook starts with designing the shape. The supplier uses CAD software to create the exact cut pattern required. Once approved, a die is produced using steel-rule blades shaped and mounted onto a wooden or metal base.

Step 2: Material Preparation

Before cutting, the selected materials must be ready. This includes trimming paper, cardstock, or specialty cover materials to the appropriate size and checking for GSM thickness and flexibility.

Step 3: Die-Cutting Execution

The prepared material is placed over the die on a die-cutting press. Depending on complexity, machines apply hydraulic or manual pressure to create precise cuts. Automated vision systems in 2025 ensure micrometer-level alignment.

Step 4: Finishing Touches

After die-cutting, elements like printing, embossing, debossing, foiling, lamination, or spot UV are added. These treatments bring the notebook to life, enhancing texture, color vibrancy, and brand identity.

Step 5: Notebook Assembly

Finally, die-cut components are assembled using spiral binding, saddle stitching, perfect binding, or hardcover casing. The result: a functional notebook that feels like a custom art piece.

Applications of Die-Cut Notebooks

Brand Promotion: Custom shapes create strong brand identity and shelf appeal

Seasonal Collections: Limited-edition shapes for holidays, back-to-school, etc.

Corporate Gifting: Memorable notebooks for VIP clients or staff

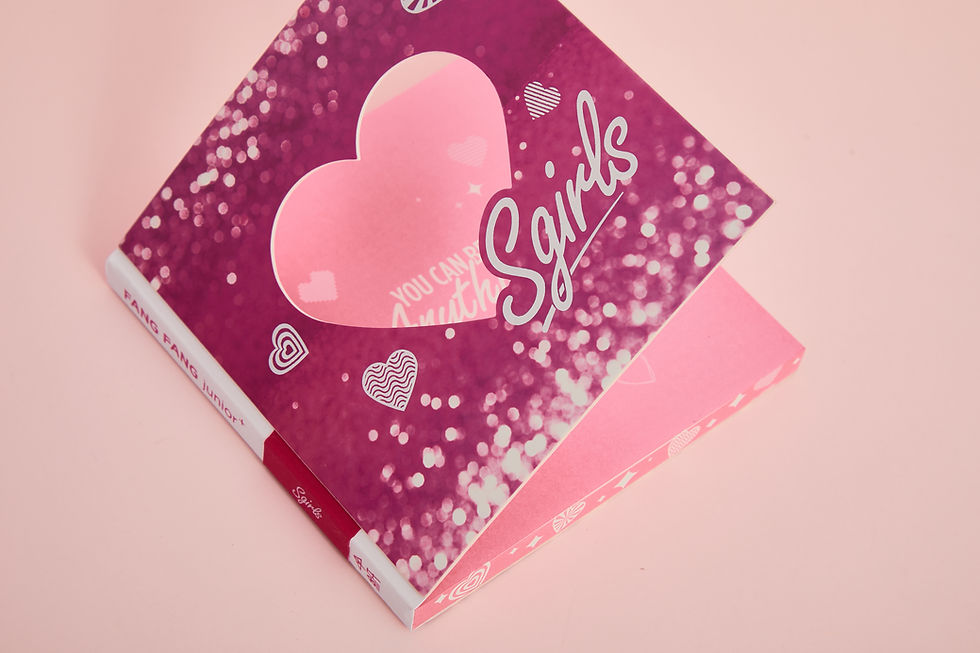

Kids' Stationery: Fun shapes like animals, stars, hearts

Creative Brands: Ideal for art, fashion, and design-themed series

Why Lion Paper is Your Trusted Die-Cut Notebook Manufacturer

In-house Die-Cutting Facilities: We invest in high-precision die-cutting presses.

Fast Prototyping: Custom sample in 5-7 days.

Quality Control: ISO9001 certified, 10+ QA inspectors, full-process video records.

Global Support: China & Cambodia base + Korea partner, serving the USA, UK, Europe.

Whether you’re a brand, buyer, or distributor, we’re here to help you bring your vision to life with stunning die-cut designs. Contact us today to start your custom notebook journey.

—Leo Xia, CEO, Lion Paper Products

You design, we deliver.

FAQs:

Q1: What materials can be used for die-cutting notebooks?

A: Most commonly used are art paper, kraft, greyboard, specialty textured paper.

Q2: Can I combine die-cutting with other effects?

A: Yes—embossing, foil stamping, UV, and more.

Q3: What are the cost factors in die-cut notebook production?

A: Die creation, material type, order volume, finishes...

Q4: Can Lion Paper help me develop a custom shape?

A: Absolutely. From concept to sample, we’re your partner.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition.

Comments