A Complete Guide to Custom Leather Notebooks

- Leo Xia

- Nov 5, 2025

- 8 min read

A custom leather notebook is a wholesale-ready notebook or journal with a leather (or leather-like) cover, tailored by size (A6/A5/B5), paper (usually 80–120 gsm), binding (Smyth sewn, Wire-O, Perfect, or refillable), and branding (emboss, deboss, foil). For B2B buyers, match material to brand tier, pick paper for ink behavior, choose a binding for durability vs. cost, and select a finish that fits your logo style and lead-time. Use the checklist below to manage MOQ, proofs, and compliance before PO.

Quick Content Reach:

Introduction

If you source notebooks at scale—whether for a retail chain, a marketplace brand, corporate gifting, or education—choosing the right custom leather notebook isn’t just about aesthetics. You’re balancing unit economics, durability, brand presentation, SKU consistency, compliance, and logistics risk.

In this guide, I map each decision—material → size → paper → binding → finish—to a specific business outcome: sell-through rate, returns, review quality, and reorder velocity. I also include a pragmatic Buying Checklist to cut sampling loops and de-risk your PO.

Questions about specs or pricing? Email us at Leoxia@lion-paper.com or WhatsApp +86 137 5075 6354.

Common cover material options for leather notebooks

Genuine leather

“Genuine leather” covers a spectrum—typically top-grain or corrected-grain for consistent surface, and full-grain in premium lines where natural markings and patina matter.

Look & feel: Warm handfeel, natural grain, ages with a patina; ideal for executive or heritage collections.

Durability: High; resists corner wear better than synthetics when paired with rounded corners and edge paint.

Color range: Natural tones dominate; aniline/semi-aniline dyes preserve character; pigmented finishes add uniformity.

Use cases: C-suite gifts, premium retail, collector editions, leather journal notebook lines for brand storytelling.

Cost & lead-time: Highest of the three; factor in dye-lot control and slightly longer sampling for color matching.

Faux leather

Also called PU or vegan leather.

Look & consistency: Excellent color control and surface uniformity across large POs; wide palette including seasonal colors.

Performance: Good abrasion and stain resistance; stable for mass retail where returns risk must be low.

Sustainability notes: Water-based PU and recycled backers exist; request specs and test reports if your channel requires them.

Use cases: Fashion-forward collections, color-rich SKUs, corporate programs requiring strict color codes.

Cost & lead-time: Competitive; fast sampling; predictable yield—useful for promotions and marketplace launches.

Bonded leather

Bonded leather mixes leather fibers with binders, then embosses a grain.

Look & feel: Leather-like appearance at value price points; less natural texture than genuine leather.

Durability: Adequate for promotional and seasonal lines; not ideal for heavy daily carry.

Use cases: Entry-level leather notebooks for price-sensitive channels, giveaways, or short-run corporate events.

Cost & lead-time: Lowest cost; fastest to turn when budgets are tight.

Common size of leather notebooks

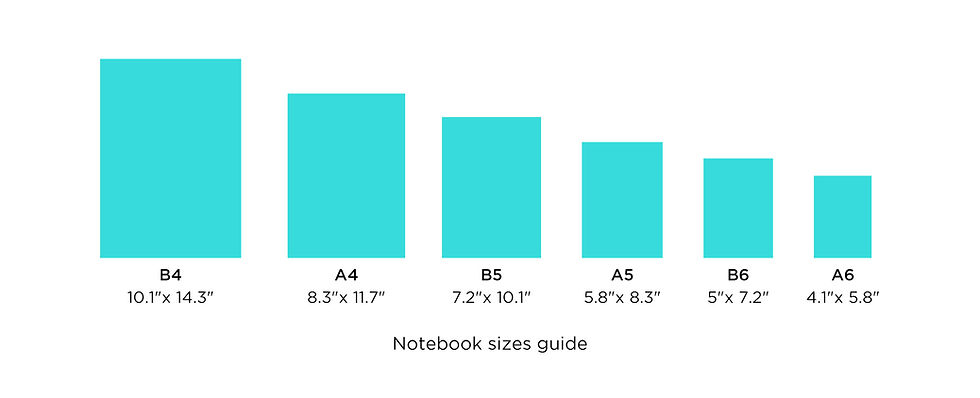

A6/A5/B5

A6 (approx. pocket size): Ultra-portable; field notes, on-the-go sales calls, conference giveaways.

A5 (everyday standard): Best all-rounder for retail; balances writeable area and portability; the default for most custom leather notebook programs.

B5 (wider page): Favored by planners and designers who want more landscape for schematics and content layouts.

Lined / Dot Grid / Blank / Planner

Lined: General writing, meeting minutes, academic notes—your “bread-and-butter” for leather notebooks.

Dot Grid: Designers, bullet journalers, PMs; flexible for sketches + writing; pairs well with 100–120 gsm.

Blank: Artists and sketchnoters; consider thicker paper to reduce show-through.

Planner layouts: Dated/undated weeklies, task blocks, yearly goals; sell as a series with accessories (pockets, tabs, pen loops).

Paper Weight & Quality

Paper drives perceived quality and reviews.

80–100 gsm: Everyday writing; keeps book weight down; good for ballpoint/gel.

100–120 gsm: “Fountain-pen friendly” territory for many inks; reduced feathering/bleed-through; ideal for premium leather journal notebook lines.

>120 gsm: Sketch/marker-friendly pages; consider page count reduction to control spine bulk.

Surface & opacity: Smooth calendaring supports crisp lines; higher opacity improves double-sided use; acid-free specs aid archival stability.

Compliance & safety: For global retail, maintain material testing (e.g., Prop 65, CPSIA where applicable) on papers and inks.

Common binding options for leather notebooks

Selecting binding is a business decision: durability, lay-flat behavior, aesthetic, and cost.

Smyth-sewn (section sewn, case-bound): Signatures stitched, excellent durability and lay-flat; premium feel; higher unit cost; best for flagship lines and gift sets.

Perfect binding (PUR/EVA): Clean square spine, efficient for mid-to-high volumes; modern look; not as lay-flat as sewn; compelling for mass retail and catalog programs.

Wire-O / Spiral: Opens fully flat; great for note-taking, planners, and calendar products; visible metal element is “functional chic”; slightly less formal for executive gifts.

Traveler’s / Refillable: Elastic or ring systems with swappable inserts; drives recurring insert sales and community engagement; ideal for DTC retention.

Thread-stitched softcover: Lightweight, flexible; a sweet spot between perfect and Smyth; good for creative series with lower MOQ variants.

Tip: For heavy daily use notebooks in bags, combine rounded corners + sewn binding + 100–120 gsm to maximize lifespan and reviews.

Common post-press finishes for custom leather notebooks

Embossing

Raised impression of your logo or pattern.

Effect: Visual pop with a tactile lift; best on smoother leathers to avoid grain “noise.”

Artwork tips: Clean vector art; avoid ultra-fine lines; mind die size vs. cover curvature.

When to use: Premium retail where subtle brand recall matters and you want a non-color decoration.

Debossing

Pressed-in (sunken) impression into the cover.

Effect: Refined, understated, very popular on custom leather notebook covers; pairs well with rustic or textured grains.

Coverage: Works for larger fields than emboss; consider heat + dwell time to avoid burnishing marks on sensitive finishes.

When to use: Corporate logos needing high legibility across various lighting conditions.

Foil stamping

Metallic or pigmented foil applied with heat and pressure.

Effect: High contrast and “giftable” sparkle; golds, silvers, and contemporary mattes (black/white/rose gold).

Durability: Excellent on even surfaces; request rub tests for dark mattes.

When to use: Holiday lines, premium gift sets, retail packaging tie-ins; combine with deboss for depth-plus-shine.

Buying Checklist

Use this list to compress sampling cycles and lock quality before PO.

Target persona & price band: Executive gift, student, designer, corporate promo—decides material and paper.

Cover material: Genuine (tier, dye), PU/vegan (coating type), or bonded (value line).

Color management: Pantone refs; lightfastness expectations; tolerance by channel.

Size: A6/A5/B5—confirm finished size vs. trim; page count vs. spine bulk.

Layout: Lined / Dot / Blank / Planner; tabbing and section dividers if planner.

Paper spec: gsm, opacity, smoothness, acid-free; fountain-pen behavior; ink compatibility.

Binding: Smyth sewn / Perfect / Wire-O / Refillable; lay-flat requirement; corner radius.

Branding finish: Emboss / Deboss / Foil; die size; position; registration tolerance.

Accessories: Pen loop, elastic band, ribbon, pockets, belly band, gift box, sleeve.

Artwork package: Vector files (outlined), white-ink or foil layers, bleed/safe margins.

Samples plan: Concept sample → pre-production sample → bulk-ready “golden” sample; sign-off protocol.

Quality controls: Incoming materials check, in-process checks, final AQL; define defect photos and tolerances.

Compliance: FSC paper availability; facility audits (e.g., BSCI/SMETA); material tests (e.g., Prop 65/CPSIA if required by channel).

Packaging: Retail barcode placement, polybag or kraft wrap, carton strength, drop test standard, pallet fit.

Forecast & buffers: Seasonality, color breaks, safety stock for hero SKUs.

Lead-time & logistics: Ex-works vs. FOB; consolidation options; delivery calendar by region.

Cost model: Unit + tooling (dies/plates) + accessories + packaging + freight; tiered pricing by volume.

After-sales: Damage allowance, replacement policy, and rapid-reorder mechanism.

Concise Summary Table

Decision Area | Best-Fit Options | Why It Matters | Notes for B2B Buyers |

Cover Material | Genuine / PU / Bonded | Brand tier, durability, consistency | Genuine for premium; PU for color control; bonded for value lines |

Size | A6 / A5 / B5 | Use case & sell-through | A5 is the hero; add A6 portability and B5 width |

Layout | Lined / Dot / Blank / Planner | Persona fit | Pair Dot with 100–120 gsm; planners drive repeat buys |

Paper | 80–120 gsm | Ink behavior & reviews | Heavier paper = less bleed; manage page count |

Binding | Smyth / Perfect / Wire-O / Refillable | Durability vs. cost | Sewn for premium; Wire-O for planners; refillable for retention |

Finish | Emboss / Deboss / Foil | Shelf impact | Deboss for clarity on textured leathers; foil for gifting |

Compliance | FSC, ISO9001, BSCI/SMETA, Prop 65/CPSIA | Channel access | Lock documents early to prevent delays |

Logistics | Lead-time, carton spec, pallets | On-time in-full (OTIF) | Define milestones and buffers in PO |

Final Words

A leather notebook program scales smoothly when each spec is tied to a commercial outcome: material informs brand tier, paper drives reviews, binding controls durability, finishes deliver shelf impact. If you align these with your channel’s margins and compliance needs, your leather notebooks line becomes both delightful to use and reliable to replenish.

Tell us your target persona, price band, and any existing sample you like. We’ll translate that into a spec, send a 5–7 day concept sample, and map a milestone plan from PO to delivery.

Ready for a quote or sample? Email your target price band and quantity!

Contacts: Leo Xia (CEO) — Leoxia@lion-paper.com | WhatsApp +86 137 5075 6354

Lion Paper Products — factories in China & Cambodia, partner facility in South Korea; 30+ pieces of equipment (Heidelberg printing, automatic stamping, laminating, spiral binding, die-cutting, visual positioning), ISO9001 & SQP; supported by R&D, showroom, and a dedicated QC team with recorded inspections.

—Leo Xia, CEO, Lion Paper Products

You design, we deliver.

FAQs:

Q1: What paper weight is best for everyday writing?

A: 80–100 gsm balances weight and opacity for ballpoint/gel inks while keeping shipping and spine bulk reasonable.

Q2: For fountain pens, should we go thicker paper?

A: Often 100–120 gsm reduces feathering/bleed-through; request ink tests on your exact stock before PO.

Q3: Which binding lasts longest in daily carry?

A: Sewn (section sewn) with rounded corners; it lays flatter and resists page pull-out over time.

Q4: Embossing vs. debossing—how do I choose?

A: Emboss (raised) gives visual pop; deboss (sunken) reads clearly on textured leathers and feels refined.

Q5: When is foil stamping the right choice?

A: Holiday lines, giftable SKUs, or when you need high contrast branding; confirm rub resistance on dark mattes.

Q6: A6, A5, or B5—what sells best?

A: A5 is the default hero; add A6 for portability and B5 for planner/design audiences to widen reach.

Q7: How do we control color across big POs?

A: Lock Pantone targets at sample stage; define tolerances; request production drawdowns and lightfastness notes.

Q8: What’s a smart accessory bundle?

A: Elastic band, ribbon bookmark, rear pocket, pen loop, and gift box—adds value without complex assembly.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition!

About Lion Paper

Company Name: Lion Paper Products

Office Address: 20th floor, Chuangyedasha Building, No. 135, Jinsui Road, Jiaxing City, Zhejiang Province, China

Factory Address: No.135, Xuri Road, Jiaxing City, Zhejiang, China

Email: Leoxia@lion-paper.com

Audit Certifications: ISO9001:2015/FSC/SEDEX SMETA/Disney FAMA/GSV/SQP

Comments