Best 2026 Guide to Paper Weight Conversion: GSM, LB, PT, MM for Custom Notebook

- Leo Xia

- Sep 19, 2025

- 12 min read

When you buy custom notebooks and planners in bulk, understanding paper weight isn’t just a technicality—it impacts the look, feel and durability of your product. In most of the world paper is described in grams per square metre (GSM), while in North America it’s common to see pounds (LB or #). There are also points (PT) to express thickness and millimetres (MM) for precision measurements. This article explains what those units mean, how to convert between them, and how to choose the right stock for your notebooks, journals and planners. Whether you’re a stationery buyer, product manager or CEO sourcing notebooks, this guide will demystify paper weight and help you make informed decisions.

Quick Content Reach:

Why Paper Weight Matters for Custom Notebooks

As the CEO of Lion Paper Products I’ve spent more than twenty years helping retailers and wholesalers choose paper for custom stationery. The weight and thickness of your paper influence the writing experience, the sturdiness of the notebook, the type of binding you can use, and even shipping costs. Higher GSM papers are heavier and more opaque, providing a premium feel and resisting show‑through. Thinner papers can keep thick journals light and flexible but may feel flimsy or allow ink to bleed. In North America paper thickness is often described in points; 10–15 pt stock is considered thin and ideal for brochures or business cards, while 16–24 pt gives a more substantial feel. Buyers who understand these differences can specify exactly what they need instead of relying on generic descriptions like “80 lb paper,” which vary by paper category.

Choosing the right paper weight also affects production efficiency. Heavier papers require stronger machinery, can increase shipping costs and may extend production times, while very thin papers may tear or jam if your supplier lacks the proper equipment. At Lion Paper Products we invest in over 30 pieces of equipment—including Heidelberg printing machines and automatic punching and binding machines—to handle a wide range of stock. Our quality control team and R&D lab ensure each notebook meets your standards.

Understanding the Units: GSM, LB, PT and MM

GSM – Grams per Square Metre

GSM measures how many grams a sheet of paper weighing one square metre weighs. It is a straightforward metric because it doesn’t change with sheet size; a 80 gsm sheet has the same mass per square metre whether it’s A5 or A0. Higher GSM means heavier, denser paper; for example, 20 pt card stock from Jukebox Print weighs about 460 gsm and provides a durable feel.

LB – Pounds per Ream

LB (also written as #) measures the weight of a ream of paper in its uncut size. The basic size varies by paper type: 500 sheets of bond paper (17 × 22 inches) weighing 80 lb are called 80 lb bond, while 500 sheets of cover paper (20 × 26 inches) weighing 80 lb are 80 lb cover. Because each paper category has a different basic size, two papers with the same pound rating can have very different thicknesses; for example, an 80 lb cover stock is heavier and stiffer than an 80 lb text stock. This is why converting between GSM and LB requires knowing whether you’re dealing with text, cover or other categories.

PT – Points

PT describes paper thickness. One point equals one‑thousandth of an inch, so a 10 pt sheet is 0.010 inches thick. Points are commonly used for card stocks and packaging; 10–15 pt stocks are considered thin and good for standard brochures or business cards, while 16–24 pt stocks are thicker and provide a premium feel. PT is not a weight measurement, but it correlates with GSM because heavier papers usually measure thicker. Manufacturers often provide charts relating PT to GSM for common card stocks.

MM – Millimetres

MM expresses thickness directly. It’s a metric measurement frequently used alongside GSM to ensure that paper will not only have the right weight but also fit into specific machinery or enclosures. Converting PT to MM involves multiplying by 0.0254 (because one inch equals 25.4 mm); a 10 pt paper measures about 0.254 mm. When designing notebooks, understanding millimetre thickness helps you calculate spine widths for perfect binding or wire‑o binding.

How to Convert Between Paper Weight Units

Converting between GSM, LB, PT and MM can be confusing because each unit measures different properties. The formulas below use industry standards for text and cover paper. Always confirm with your supplier which category your stock falls into.

GSM to LB (Text and Cover)

Formula for text paper: 1 gsm ≈ 0.676 lb text. Multiply the GSM value by 0.676 to get the corresponding pound weight. For example, a 200 gsm text paper weighs about 135 lb (200 × 0.676).

Formula for cover paper: 1 gsm ≈ 0.369 lb cover. Multiply the GSM value by 0.3695. A 200 gsm cover paper weighs about 73.9 lb (200 × 0.3695).

Example: 157 gsm paper converts to roughly 106 lb text or 58 lb cover.

LB to GSM

Formula for text paper: 1 lb text ≈ 1.48 gsm. Multiply the pound weight by 1.48 to convert to GSM.

Formula for cover paper: 1 lb cover ≈ 2.708 gsm. For example, 80 lb cover stock converts to about 216 gsm (80 × 2.708).

PT to LB and GSM

A general guideline from printers is that 8 pt cardstock corresponds to about 80 lb cover, 12 pt to 90 lb cover, 14 pt to 111 lb cover, 16 pt to 129 lb cover and 18 pt to 148 lb cover.

To convert PT to GSM, suppliers use standard charts. Common conversions are: 8 pt ≈ 200 gsm, 12 pt ≈ 250 gsm, 14 pt ≈ 300 gsm, 16 pt ≈ 350 gsm, and 18 pt ≈ 400 gsm. These are approximations; actual weight depends on paper density.

PT to MM

Because one point equals 0.001 inches, multiply by 0.0254 to convert to millimetres. A 10 pt sheet (0.010 in) becomes 0.254 mm. Many paper charts provide reference values: 8 pt ≈ 0.203 mm, 10 pt ≈ 0.254 mm, 12 pt ≈ 0.305 mm, 14 pt ≈ 0.356 mm, 16 pt ≈ 0.406 mm and 18 pt ≈ 0.457 mm.

Quick Conversion Tables

Below are concise tables summarising common conversions (remember that values vary slightly by manufacturer):

Common GSM to LB Conversions

GSM (text) | Approx. LB (text) | GSM (cover) | Approx. LB (cover) |

80 | 54 | 157 | 58 |

100 | 68 | 200 | 74 |

105 | 71 | 250 | 92 |

120 | 81 | 300 | 111 |

128 | 86 | 350 | 129 |

Source: conversion formulas from BookPrintingChina and QinPrinting.

Common LB to GSM Conversions

LB (text) | Approx. GSM (text) | LB (cover) | Approx. GSM (cover) |

50 | 74 | 60 | 163 |

60 | 89 | 70 | 190 |

70 | 104 | 80 | 217 |

80 | 118 | 90 | 244 |

90 | 133 | 100 | 271 |

100 | 148 | 110 | 298 |

110 | 163 | 120 | 325 |

Source: conversion formulas bookprintingchina.com.

Comparing Thickness: GSM vs PT vs MM

Weight and thickness are related but not identical. Two papers with the same GSM can have different thicknesses if they are coated or uncoated, and some card stock uses PT to emphasise stiffness. Recognising these relationships helps you pick the right feel for your notebooks.

Uncoated vs coated – Within the same GSM, uncoated papers are usually thicker than coated papers. For example, a 120 gsm uncoated offset paper measures around 0.14 mm thick, while a 128 gsm glossy art paper is about 0.12 mm. Coated papers compress fibres tightly to accept ink evenly, reducing thickness for the same weight.

Offset paper thickness range – In a reference table, 60 gsm offset paper is about 0.08 mm thick, 80 gsm is 0.10 mm, 100 gsm is 0.12 mm, 140 gsm is 0.16 mm, 160 gsm is 0.18 mm and 180 gsm is 0.22 mm. These values help when calculating the thickness of a notebook’s text block.

Card stock thickness – 8 pt card stock is about 0.203 mm thick, while 18 pt is around 0.457 mm. Premium business cards use 16–20 pt stock (350–460 gsm) that feels luxurious. For notebook covers, 10–16 pt cover stock provides a balance of durability and flexibility.

How GSM Correlates with Feel and Usage

Higher GSM papers feel more substantial and resist bending or tearing. A 20 pt (460 gsm) card stock is preferred for premium business cards because it balances durability and elegance. Conversely, interior pages of notebooks often use 70–100 gsm paper to keep the book comfortable to write in and not too heavy. Jukebox Print notes that 80 lb text stock (around 118 gsm) is commonly used for the inside pages of saddle‑stitched books . Dense papers are ideal for special invitations or packaging where longevity and premium feel matter.

Selecting the Right Paper Weight for Different Notebook Products

Different notebook formats—journals, planners, bullet journals or business notebooks—require different paper weights to deliver the desired writing experience and durability.

Lightweight Pages for Everyday Writing

For journals and planners that will be written on daily, choose 70–100 gsm uncoated or lightly coated paper. This range offers good opacity to prevent ink show‑through while remaining thin enough to allow many pages. Newspapers and standard office printing use 80–110 gsm stock. For budget‑friendly notebooks, 60–80 gsm paper may be acceptable, but heavier fountain‑pen users might prefer 100 gsm.

Mid‑weight Stock for Premium Journals and Planners

Luxury journals, bullet journals and planners often use 100–140 gsm paper. This thicker paper feels more substantial under the pen, supports heavier inks and reduces bleed‑through. Mid‑weight stock is also suitable for planner pages that include stickers or markers. A 120 gsm paper (0.14 mm thick) offers a premium feel without making the book too bulky.

Cover Materials

Notebook covers require sturdier stock to protect the pages and create a quality impression. Card stock in the 10–16 pt range (230–350 gsm) is common for soft covers. For example, 10 pt C1S (coated one side) at 230 gsm is used for posters and book covers, while 15 pt C1S (345 gsm) is suitable for business cards or hang tags. A 16 pt stock (about 350 gsm) provides more rigidity for planners, whereas 18 pt and above may be used for luxury packaging but can make a notebook harder to open. When selecting cover weight, consider the binding method—spiral or wire‑o bindings can accommodate thicker covers, while perfect binding may require flexibility.

Speciality Papers and Inserts

Some notebooks include divider pages, pockets or inserts that need extra durability. Gray board used for hard covers ranges from 600 gsm (1 mm) to 1800 gsm (3 mm) depending on thickness. Kraft paper inserts can be around 80–120 gsm, and Bible paper (thin, strong paper used in Bibles) can be as low as 30–35 gsm. Tailoring these materials to your product can enhance functionality.

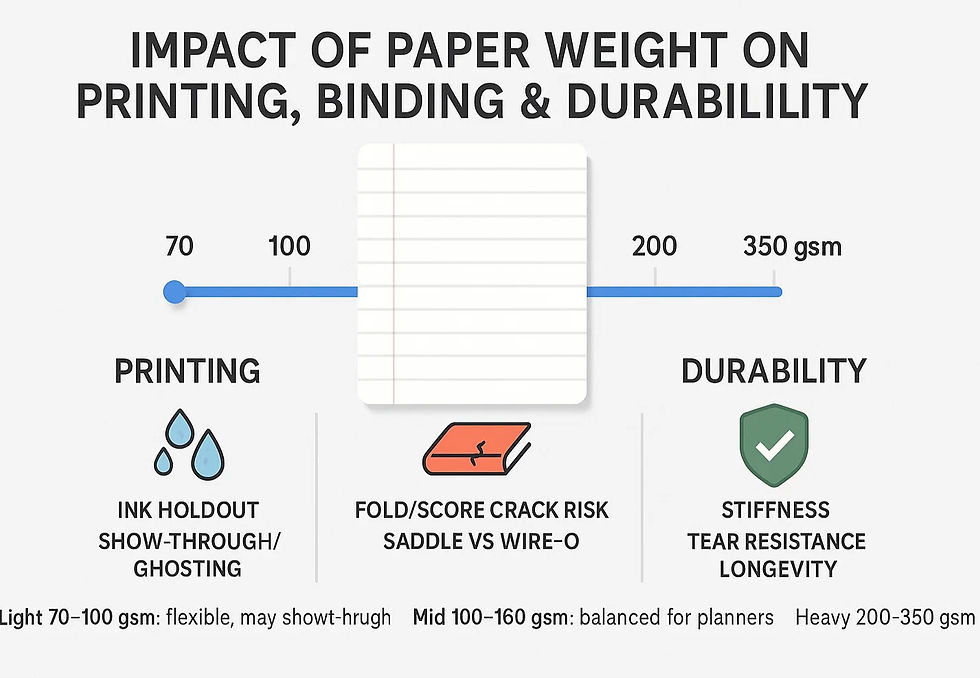

Impact of Paper Weight on Printing, Binding and Durability

Selecting paper weight is not just about feel; it influences manufacturing, printing quality and longevity.

Printing Considerations

Heavier papers absorb ink differently. High‑GSM uncoated papers may absorb more ink and appear slightly duller, whereas coated papers provide a smooth surface for sharp colour reproduction. Thicker stock also reduces show‑through, allowing double‑sided printing without bleed. However, very thick paper may crack along folds if not scored properly. When printing full‑colour spreads for planners or art journals, a 120–157 gsm coated paper will showcase vibrant imagery while maintaining flexibility.

Binding and Construction

The thickness of the paper determines the spine width and binding method. Perfect‑bound notebooks need enough spine to glue pages effectively; 300‑page journals printed on 100 gsm paper will have a spine around 30 mm, whereas the same number of pages on 70 gsm paper would be thinner. Spiral and wire‑o binding can accommodate thicker covers (up to 16 pt) and various page weights. Hard cover notebooks may use grey board cores of 1–3 mm thickness with printed cover wraps. Understanding MM measurements helps calculate spine widths and ensures machines are set correctly.

Durability and User Experience

Durability is a function of both weight and construction. Thicker paper resists tearing and maintains integrity under heavy use, while lower GSM pages might become dog‑eared or tear when turned frequently. Buyers of planners and journals often value paper that handles highlighters, pens and markers without bleeding; 100 gsm or more is recommended for this audience. For covers, 300–350 gsm stock with lamination or coating adds water and stain resistance. Incorporating sustainable materials like recycled or FSC‑certified paper also appeals to eco‑conscious consumers.

Tips for Converting Paper Weights and Working with Suppliers

As a buyer, you need to communicate clearly with international suppliers who may use different units. Here are practical tips to ensure smooth collaboration:

Clarify paper category – Ask whether the weight refers to text, cover or board stock. Conversions from GSM to LB differ by category.

Request samples – Before committing to a large order, request sample sheets or a paper sample book. Evaluating actual paper helps you assess thickness, opacity, texture and print quality. Lion Paper Products offers sample packs for notebooks, planners and journals.

Use conversion charts – Keep a conversion chart handy or bookmark this guide. Charts help you quickly translate GSM to LB and PT so you can compare offers from suppliers.

Consider end use – Specify the intended use of the notebooks (e.g., daily journal, high‑end planner, promotional giveaway) so the supplier can recommend appropriate stock. Heavy stock may be unnecessary for disposable notebooks, while premium journals need thicker paper.

Account for binding – Inform your supplier about the binding method. Some bindings require specific spine thickness or cover rigidity. Provide the page count and preferred paper weight so the spine width can be calculated accurately.

Evaluate sustainability – Inquire about certifications such as FSC, PEFC, BSCI or SMETA, and ask whether the paper contains recycled fibres. Sustainable sourcing is increasingly important for corporate buyers.

Request proofing – For complex projects, request a printed proof or dummy to check colour reproduction and overall feel. Our R&D team at Lion Paper Products can produce custom samples within 5–7 days.

Partnering with the right manufacturer can simplify these decisions. At Lion Paper Products we operate our own factories in China and Cambodia and a partner factory in South Korea to control quality and lead times. Our experienced consultants can help you choose the ideal paper weight, finish and binding for your notebooks. Whether you need 5,000 planners or 50,000 journals, we can handle everything from design tweaks to custom packaging. Get in touch today to discuss your project and receive tailored guidance—your customers will feel the difference.

Sustainability and Certifications in Paper Selection

Consumers are increasingly concerned about the environmental impact of paper products. Choosing sustainable paper not only protects forests but also enhances your brand image.

FSC certification – The Forest Stewardship Council (FSC) certifies paper from responsibly managed forests. Lion Paper Products carries FSC‑certified stocks and performs annual material tests, such as California Proposition 65 and CPSIA, to ensure compliance.

Recycled content – Recycled paper can range from 30 % to 100 % post‑consumer fibre. Our eco‑friendly paper options deliver the same print quality as virgin stock while reducing waste.

BSCI and SMETA – Beyond environmental credentials, social responsibility matters. Our factories meet BSCI, SMETA and Sedex standards, providing fair wages, protective equipment and training for every worker. This commitment ensures our products are ethically produced.

High‑quality equipment – To maintain quality while using sustainable materials, we invest in advanced machinery: automatic laminators, die‑cutting machines and visual positioning instruments ensure precision and efficiency. High‑end equipment reduces waste and improves consistency across large runs.

Final Words

By mastering paper weight conversions and understanding how different weights affect the feel, look and durability of notebooks, you can confidently work with manufacturers and request the perfect stock for your products. At Lion Paper Products we pride ourselves on helping brands bring their notebook visions to life with precision and care. Feel free to contact our team for expert advice and a custom quote—your next great notebook starts with the right paper.

—Leo Xia, CEO, Lion Paper Products

You design, we deliver.

FAQs:

Q1: What is the difference between GSM and LB?

A: GSM measures how many grams a square metre of paper weighs, providing a consistent metric worldwide. LB measures the weight of a ream (500 sheets) of a specific paper size, so the same pound rating can vary by category.

Q2: How do I convert GSM to LB for text and cover paper?

A: Multiply the GSM of text paper by 0.676 or the GSM of cover paper by 0.369 . For example, 120 gsm text paper is about 81 lb (120 × 0.676) and 200 gsm cover paper is about 74 lb (200 × 0.3695).

Q3: Why does an 80 lb cover stock feel thicker than an 80 lb text stock?

A: Pound ratings are based on different sheet sizes; 80 lb cover stock uses a smaller basic size (20 × 26 inches), while 80 lb text stock uses a larger size (25 × 38 inches). The cover stock therefore contains more material per sheet and feels thicker.

Q4: What paper weight should I choose for the interior pages of a journal?

A: For daily writing, select 70–100 gsm uncoated or lightly coated paper to balance opacity and flexibility. Premium journals may use 100–140 gsm for a more luxurious feel.

Q5: How thick should notebook covers be?

A: Soft covers commonly use 10–16 pt card stock (230–350 gsm); 15 pt (about 345 gsm) is standard for premium covers. For hard covers, grey board of 1–3 mm thickness (600–1800 gsm) provides rigidity.

Q6: What is the best paper weight for planners that include stickers and markers?

A: Choose mid‑weight paper in the 100–140 gsm range. It provides enough stiffness to support stickers and prevents bleed‑through from markers while keeping the planner manageable in thickness.

Q7: Is recycled paper suitable for high‑quality notebooks?

A: Yes. Modern recycled paper can achieve high whiteness and smoothness comparable to virgin stock. Many of our recycled papers carry FSC certification and meet CPSIA and Proposition 65 standards for safety, making them ideal for eco‑friendly journals and planners.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition!

About Lion Paper

Company Name: Lion Paper Products

Office Address: 20th floor, Chuangyedasha Building, No. 135, Jinsui Road, Jiaxing City, Zhejiang Province, China

Factory Address: No.135, Xuri Road, Jiaxing City, Zhejiang, China

Email: Leoxia@lion-paper.com

Audit Certifications: ISO9001:2015/FSC/SEDEX SMETA/Disney FAMA/GSV/SQP

Comments