What is the difference between perfect bound and spiral bound?

- Lion Paper Team

- Aug 18, 2025

- 14 min read

Updated: Aug 19, 2025

Quick Content Reach:

Introduction

Selecting the right binding method isn’t just a technical decision; it shapes how your notebook or planner looks, feels and performs in daily use. In the stationery world, different bindings are defined not only by paper quality and design but also by how the pages are held together. Two of the most popular methods—perfect binding and spiral binding—offer very different experiences. Perfect binding creates a sleek, book‑like spine using adhesive, while spiral binding threads a coil through punched holes for maximum flexibility thepremierprintgroup.comthepremierprintgroup.com. Understanding the difference between perfect bound and spiral bound empowers wholesalers, retailers and brands to select the right format for their customers. Throughout this article you’ll find embedded examples, industry data and advice drawn from many years of experience in global stationery manufacturing.

If at any point you need help tailoring a type of notebook to your brand, feel free to contact us or send a message via WhatsApp for a personal consultation.

Binding fundamentals: why it matters

Binding holds the pages of a book, notebook or planner together, but its impact goes far beyond structural integrity. It influences everything from how the cover can be designed to how easily a book lays flat, how durable it is under repeated use, the environmental footprint of the materials, and how your product is perceived by customers. For brands selling in markets like the United States or Europe, buyers are increasingly discerning. They value sustainability, professional presentation, user experience and price. Different bindings speak to different priorities—for instance, a corporate report demands a polished appearance, while a workout journal needs to survive being folded back on itself repeatedly. In the following sections, I’ll break down how perfect and spiral binding operate and their unique advantages.

If you’re wondering which binding might suit your next order, our team at Lion Paper Products can help you specify materials and finishes that bring your notebook concept to life. Learn more!

What is perfect binding?

Perfect binding, sometimes called adhesive binding, is commonly used for softcover books, catalogues and thicker magazines. In this method the pages and cover are gathered, the spine edge is roughened to increase surface area, and a flexible adhesive is applied along the spine. The wrap‑around cover is then attached and the three open edges are trimmed for a smooth finish thepremierprintgroup.com. The result is a square spine that can be printed on and a clean, professional appearance thepremierprintgroup.com. Perfect binding is ideal for higher‑page‑count publications beyond the range of saddle stitching thepremierprintgroup.com.

Page count and specifications

A common question from buyers is how many pages are required for perfect binding. There is no single number because spine thickness depends on paper weight, but guidelines exist. Color Vision Printing advises that at least 0.125 inch (3 mm) of spine thickness is needed for the adhesive to grip properly. When using 50 lb offset paper (around 0.004 inch per sheet), that equates to about 62 pages; heavier 80 lb paper (0.006 inch per sheet) can achieve the minimum thickness in about 42 pages colorvisionprinting.com. Imprint Digital notes that perfect binding can be done on booklets as thin as 1.9 mm (around 16 pages on 190 gsm paper), but most printers recommend more pages to ensure strength imprintdigital.com. For thicker books, perfect binding comfortably accommodates hundreds of pages thepremierprintgroup.com.

When selecting perfect binding, keep in mind that the total page count must be a multiple of four due to how signatures are assembled chinaprinting4u.com. This ensures proper folding and trimming.

Our factory can calculate the exact spine width using the chosen paper stock and help you determine whether perfect binding suits your project. Feel free to send us your page count and paper preferences for a detailed quote.

Adhesives: EVA vs PUR

The adhesive used in perfect binding significantly influences durability, flexibility and environmental impact. Two main glues are used: EVA (Ethylene–Vinyl Acetate) and PUR (Polyurethane Reactive).

EVA glue is a traditional hot‑melt adhesive introduced in the 1940s. It bonds well to uncoated papers but can struggle with coated stocks colorvisionprinting.com. Because it’s thermoplastic, EVA can be reheated and reused, which reduces waste, but it can soften if a finished book is exposed to high temperatures colorvisionprinting.com. EVA cures quickly as it cools, allowing books to move to trimming soon after gluing colorvisionprinting.com. Its cost‑effectiveness makes it popular, though it offers moderate strength and flexibility colorvisionprinting.com.

PUR glue is a reactive polyurethane adhesive that forms chemical bonds with moisture in the air and paper colorvisionprinting.com. This polymerisation gives PUR superior strength and flexibility; books bound with PUR resist page pull‑out by 60 % more than those using EVA colorvisionprinting.com. PUR maintains its flexibility over time and can bond to a wide range of substrates, including coated and recycled papers colorvisionprinting.com. It requires less glue volume, leading to a neater spine and reduces the risk of adhesive oozing colorvisionprinting.com. Although PUR takes longer to cure and cannot be reheated, the resulting bond withstands extreme temperatures better than EVA colorvisionprinting.com.

From a sustainability perspective, PUR is considered more environmentally friendly than EVA. The Park Communications sustainability guide notes that perfect binding relying on EVA is the least sustainable option among glue‑based bindings due to higher energy use and difficulty separating the glue during recycling parkcom.co.uk. By contrast, PUR requires about 70 % less glue and cures at lower temperatures, reducing energy consumption parkcom.co.uk.

Advantages of perfect binding

Professional appearance – Perfect binding yields a sleek, polished look with a square spine that can be printed on for branding or titling thepremierprintgroup.com. This makes it ideal for novels, catalogues, annual reports and high‑end planners printed.com.

Cost‑effective for medium to large runs – Compared with case binding, perfect binding is less expensive and lighter thepremierprintgroup.com. Once a run exceeds a few hundred units, the per‑unit cost becomes very competitive.

Compact storage – The flat spine enables books to stack neatly, maximising shelf space thepremierprintgroup.com. This is important when shipping to distributors or storing inventory.

Versatility – Perfect binding works with various paper types and weights printed.com. Combined with features like spot UV, foil stamping or soft‑touch lamination, it can produce a premium product.

Durability – When PUR adhesive is used, perfect bound books resist page pull‑out and maintain flexibility even after repeated opening colorvisionprinting.com.

Branding potential – The printable spine allows easy identification in retail environments and supports cross‑selling of series or collections printed.com.

If you envision your type of notebook appearing on retail shelves or as part of a corporate kit, perfect binding may be the right choice. Contact us to discuss cover finishes, embossing or foil stamping that elevate your product.

Limitations of perfect binding

Doesn’t lay fully flat – Because pages are glued together at the spine, perfect bound books do not open completely flat. This can make writing or scanning more difficult compared with spiral bound books printbindship.com.

Higher minimum page count – The spine needs sufficient thickness for adhesive to hold; thin booklets may not achieve the required thickness and may instead require saddle stitching or a thicker paper colorvisionprinting.com.

Less sustainable with EVA – As noted, traditional perfect binding using EVA glue consumes more energy and is harder to recycle parkcom.co.uk. Choosing PUR mitigates this issue but may cost slightly more.

Potential spine cracking – Lower‑quality EVA adhesives can crack with heavy use or extreme temperatures, causing pages to detach colorvisionprinting.com.

Many of these limitations can be addressed through material choices and manufacturing process. For example, using PUR glue, selecting flexible paper stocks and adding a soft‑touch laminate can improve durability. Reach out if you would like samples of various bound notebooks to evaluate in person.

What is spiral binding?

Spiral binding—also called coil binding—threads a continuous coil of plastic or metal through punched holes along the edge of the pages thepremierprintgroup.com. This binding method is straightforward: after the pages are printed and collated, evenly spaced holes are punched along the binding edge, then a coil is woven through the holes. The coil is crimped at both ends to prevent unravelling. Common coil materials include durable plastic (often PVC or PET) and metal. Plastic coils are cost‑effective and available in many colours, while metal coils provide added strength and a premium feel citypressinc.com. Spiral binding is widely used for notebooks, manuals, calendars, journals and planners where lay‑flat capability is essential thepremierprintgroup.com.

Benefits of spiral binding

Lay‑flat and 360‑degree rotation – Spiral bound books open completely flat and pages can rotate a full 360 degrees without damaging the spine thepremierprintgroup.com. This makes them ideal for hands‑on applications such as cookbooks, training manuals, planners and sketchbooks where users need both hands free thepremierprintgroup.com.

Flexible page counts – Coils come in various diameters, allowing this binding to accommodate a wide range of page counts from just a few pages to several hundred thepremierprintgroup.com. When your design requires variable thickness or you anticipate adding inserts, spiral binding offers adaptability.

Durability – Because each page is free to move independently, there is minimal stress on the paper when opening and closing the book. This contributes to longevity, especially when metal coils are used citypressinc.com. AlphaGraphics notes that coil bound booklets are durable and resistant to snags and tears, making them well suited for high‑use environments alphagraphics.com.

User‑friendly – The lay‑flat design enhances readability and writing comfort. For example, teachers prefer spiral bound manuals and workbooks because students can write in them easily and they stay open on a desk curcioprinting.com.

Low minimum order quantities – Spiral binding is cost‑effective for small print runs. It doesn’t require the glue set‑up and trimming that perfect binding does, making it economical for prototypes or short‑term projects printbindship.com.

Customisation options – You can choose coil colours, add index tabs and mix paper stocks. Wire‑O binding (double loop wire) offers a more refined look with similar functionality, though at higher cost thepremierprintgroup.com.

Our factories offer plastic coils in multiple colours and diameters, as well as metal Wire‑O for premium projects. If you’d like help choosing coil size or style, send us your specifications and we will recommend the best option.

Drawbacks of spiral binding

Less formal appearance – Some customers perceive spiral bound books as more casual or utilitarian. For luxury journals or corporate presentations, the exposed coil may not convey the desired image curcioprinting.com.

No printable spine – The absence of a spine means you cannot print titles or branding along the edge. This can make organisation on shelves more challenging curcioprinting.com.

Potential coil damage – Plastic coils can deform if packed tightly, and metal coils may bend. When coiled books are mishandled, pages can catch on the coil printbindship.com. Shipping and storage therefore require more care.

Not always accepted by retail distributors – Some retailers and libraries prefer perfect or case bound books because coil binding is less common on retail shelves printbindship.com.

Limited capacity for very thick books – Although coil diameters vary, extremely thick books may become unwieldy if bound with a large coil alphagraphics.com. In such cases a different binding method like case binding may be more appropriate.

Despite these limitations, spiral binding remains the preferred choice, especially where function and ease of use are paramount. You can always add cover embellishments—such as laminated covers, pockets or elastic closures—to enhance presentation. If you want to create a high‑end coil bound planner, we can propose design elements that elevate its look while retaining the practical benefits. Try Now.

Comparing perfect bound vs spiral bound

To help you visualise the differences between these binding methods, the table below summarises their key characteristics. Remember that actual performance also depends on paper quality, cover stock and the expertise of your printing partner. We’re happy to advise on the best choice for your specific type of notebook.

Aspect | Perfect Bound | Spiral Bound |

Binding process | Pages collated, spine roughened, adhesive applied, wrap‑around cover attached and trimmed thepremierprintgroup.com | Pages punched along one edge; a continuous plastic or metal coil threaded through holes and crimpedthepremierprintgroup.com |

Page range | Typically 40–400 pages depending on paper weight colorvisionprinting.comthepremierprintgroup.com | Wide range, from a few pages to several hundred; coil size adjusts accordingly thepremierprintgroup.com |

Lay‑flat ability | Does not lay fully flat; pages held by glue restrict opening printbindship.com | Lays completely flat; pages rotate 360° and can fold back on themselves thepremierprintgroup.com |

Spine printing | Yes; square spine can display titles, logos or branding thepremierprintgroup.com | No; coil binding lacks a spine for printing, making shelf identification harder curcioprinting.com |

Durability | Good when using PUR; EVA may crack or loosen under heat/cold colorvisionprinting.com | Very durable; pages turn independently, reducing stress; metal coils add strength alphagraphics.comcitypressinc.com |

Appearance | Sleek, professional; suits novels, catalogues, corporate reports printed.com | Functional, casual; suitable for manuals, workbooks, planners, calendars thepremierprintgroup.com |

Cost per unit | Economical for medium‑to‑high quantities; more expensive than saddle stitching but cheaper than case binding thepremierprintgroup.com | Cost‑effective for small runs; coil binding equipment has lower set‑up costs and fewer finishing operations printbindship.com |

Customisation | Cover can be printed, laminated, foil stamped; spine width allows for branding printed.com | Coil colour and diameter can be customised; index tabs, divider pages and cover materials add variety thepremierprintgroup.com |

Sustainability | PUR glue uses less adhesive and has lower energy consumption than EVA parkcom.co.uk; EVA glues are less sustainable parkcom.co.uk | Coils are typically made from plastic or metal; recyclable metal coils exist, but plastic options may not be accepted by curb‑side recycling; no adhesives are used, reducing chemical content |

Common uses | Novels, textbooks, catalogues, annual reports, branded planners, high‑end journals printed.comonpressbookprinting.com | Manuals, workbooks, training guides, academic planners, journals, sketchbooks, calendars thepremierprintgroup.comcurcioprinting.com |

If you’re still uncertain which binding suits your project after reviewing the table, our sales consultants can analyse your product specifications, target market and budget to recommend the ideal notebook. Please send us a brief description and we’ll respond with customised advice.

Choosing the right binding for your project

Selecting between perfect and spiral binding involves balancing several factors. As you plan your next project, consider the following questions:

Purpose and usage – Will the notebook be used for note‑taking, reference, design sketches or as a gift? Books that need to stay open for extended periods—like cookbooks, planners and workbooks—benefit from spiral binding’s lay‑flat design thepremierprintgroup.com. Conversely, novels, corporate reports or catalogues that emphasise aesthetics and shelf presence often require the professional look of perfect binding printed.com. If you’re designing a hybrid product like a premium planner that needs both elegance and functionality, consider “lay‑flat PUR perfect binding,” which uses PUR adhesive to achieve partial lay‑flat ability curcioprinting.com.

Page count and thickness – Books with fewer than about 40 pages may not have enough spine width for perfect binding; thicker covers or alternative binding like saddle stitching may be necessary colorvisionprinting.com. Spiral binding easily accommodates thin or thick volumes by choosing an appropriate coil diameter thepremierprintgroup.com.

Reader experience – Consider how your end‑user interacts with the product. Students and professionals who annotate or write notes will appreciate the ability to fold the pages back and maintain a flat surface. Customers flipping through high‑end catalogues or gift journals may prioritise a refined look with a printed spine. Striking the right balance is key.

Budget – Perfect binding is generally more economical for large print runs, while spiral binding is cost‑effective for small runs or prototypes printbindship.com. Factor in the additional cost of PUR adhesive if you need greater durability or environmental performance parkcom.co.uk.

Distribution and marketing – If your notebooks are destined for retail shelves, a printed spine helps with merchandising and brand recognition printed.com. For digital platforms like Amazon or e‑commerce, the choice may hinge on user reviews and functional benefits rather than shelf presence.

Environmental goals – Evaluate the sustainability of materials and adhesives. PUR perfect binding uses less adhesive and has better recyclability than EVA parkcom.co.uk, while metal coils in spiral binding can be recycled more easily than plastic coils. If eco credentials are a selling point, we can source FSC‑certified paper, soy‑based inks and recyclable materials.

By answering these questions, you’ll narrow down the most suitable binding method.

Our experienced team at Lion Paper Products can analyse your requirements and propose solutions that align with your brand goals and budget. Reach out to us for a consultation—we love turning your creative ideas into tangible products.

Sustainability and innovation in binding

Environmental responsibility has become a key decision factor for many brands and consumers. Traditional perfect binding uses EVA glue, which melts during recycling and leaves plastic inclusions in the pulp parkcom.co.uk. As noted, PUR glue significantly improves sustainability because it uses less adhesive, cures at lower temperatures and can be more easily separated during recycling parkcom.co.uk. Sustainable binding goes beyond adhesives: it also involves selecting recycled or responsibly sourced paper, avoiding unnecessary lamination, and using alternative binding methods that eliminate plastic altogether. For example, textile‑based bindings like thread‑sewn binding or naked binding require little or no plastic glue; they open completely flat and offer a handcrafted aesthetic parkcom.co.uk. However, these methods are usually more expensive and suited to smaller runs or high‑end art books.

Metal‑based bindings such as half‑Canadian or wire‑O can remove plastic entirely and are robust. The Park Communications guide highlights that metal bindings, though energy intensive to manufacture, generate no plastic waste and can be recovered during recycling parkcom.co.uk. If your brand emphasises sustainability, consider exploring these options.

Our Production Team continuously tests new eco‑friendly materials and can advise on cost‑effective solutions that minimise environmental impact while maintaining quality. Feel free to ask us about FSC‑certified paper, biodegradable coatings or recycled metal coils.

Industry trends and market considerations

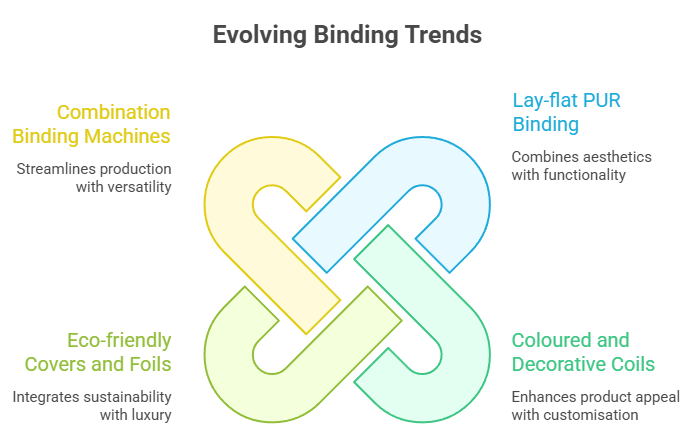

The binding landscape is evolving as designers and consumers demand both functionality and aesthetic appeal. Here are some notable trends:

Lay‑flat PUR perfect binding – Combining the polished appearance of perfect binding with near lay‑flat performance, PUR technology is gaining traction in high‑end planners and textbooks curcioprinting.com. Brands appreciate the durability and user friendliness despite slightly higher costs.

Coloured and decorative coils – To make spiral bound products stand out, manufacturers offer coils in bright colours and metallic finishes. This customisation aligns with seasonal themes or brand palettes and enhances the perceived value of everyday notebooks.

Eco‑friendly covers and foils – Designers are integrating recycled paper stocks and foils into both perfect and spiral bound products. MyBinding’s binding trends highlight eco‑friendly covers such as linen weave and chipboard that are made from recycled content mybinding.com. Finishes like foil accents add luxury without the weight of a hardcover mybinding.com.

Combination binding machines – Print shops increasingly use equipment that can handle multiple binding methods (comb, coil, wire) in one platform. This reduces overhead and shortens lead times, making it easier to prototype new types of notebook mybinding.com.

Staying ahead of these trends means partnering with a manufacturer who continually invests in equipment and innovation. Lion Paper Products has invested in more than 20 pieces of high‑end machinery, including automatic punching, laminating, spiral binding and packaging equipment. This allows us to deliver consistent quality and handle complex customisation at scale. Contact us if you’d like to incorporate any of these trends into your next notebook collection.

Final thoughts: the difference between perfect bound and spiral bound

The choice between perfect binding and spiral binding ultimately depends on your product’s purpose, audience and brand identity. Perfect binding offers a sophisticated, book‑like appearance with the ability to print on the spine, making it ideal for catalogues, novels and premium planners printed.com. When paired with PUR glue, it provides robust durability and improved sustainability colorvisionprinting.com. Spiral binding, on the other hand, delivers unmatched functionality: it opens flat, rotates 360 degrees and adapts to varying page counts thepremierprintgroup.com. This makes it perfect for manuals, workbooks, journals and sketchbooks.

As a seasoned producer of writing paper products serving markets across the United States, Europe and beyond, Lion Paper Products understands the nuances of each binding method.

Our team will gladly guide you through selecting the best type of notebook, customising covers, choosing eco‑friendly materials and ensuring your product resonates with your target audience. We invite you to explore our website or contact us directly by email or WhatsApp for a personalised consultation. Together we can craft notebooks and planners that not only meet but exceed your expectations.

FAQs:

Q1: What is the main difference between perfect bound and spiral bound notebooks?

A: Perfect bound notebooks use adhesive to glue pages to a square spine, producing a sleek, professional look. Spiral bound notebooks use a plastic or metal coil threaded through punched holes, allowing pages to lay flat and rotate 360 degrees.

Q2: Which binding is more durable?

A: A perfect bound book using PUR glue offers strong adhesion and flexibility, resisting page pull‑out. However, spiral bound notebooks distribute stress across individual pages, reducing wear and tear. Metal coils enhance durability.

Q3: Can you print on the spine of a spiral bound notebook?

A: No. Spiral bound notebooks lack a spine for printin. Perfect bound notebooks have a flat spine that can display titles and logos.

Q4: Do spiral bound notebooks accommodate more pages than perfect bound?

A: Spiral binding is highly flexible; coil diameters can be increased to handle many pages. Perfect binding can also handle hundreds of pages but requires a minimum thickness for the adhesive.

Q5: Which binding is better for notebooks that need to lay flat?

A: Spiral binding allows books to lay completely flat and fold back on themselves. Perfect bound notebooks do not lay fully flat.

Q6: How do I decide which binding is right for my notebooks?

A: Consider your product’s purpose, page count, budget, desired appearance and sustainability goals. Perfect binding suits professional presentations and high‑page‑count books. Spiral binding excels for workbooks, planners and products requiring lay‑flat use. Feel free to contact us for personalised advice.

Are you looking for a reliable manufacturer? Reach out to Lion Paper for a free quote and consultation. Let’s collaborate on creating custom writing paper products that will set your brand apart from the competition!

Comments